Foundry Sand Testing Ensuring Quality in Metal Casting

In the metal casting industry, foundry sand plays a critical role in shaping the final product. The quality of sand used in the casting process significantly influences the overall quality of the metal components produced. Therefore, foundry sand testing is an essential procedure that ensures the right properties of sand are maintained to achieve high-quality castings.

Types of Foundry Sand

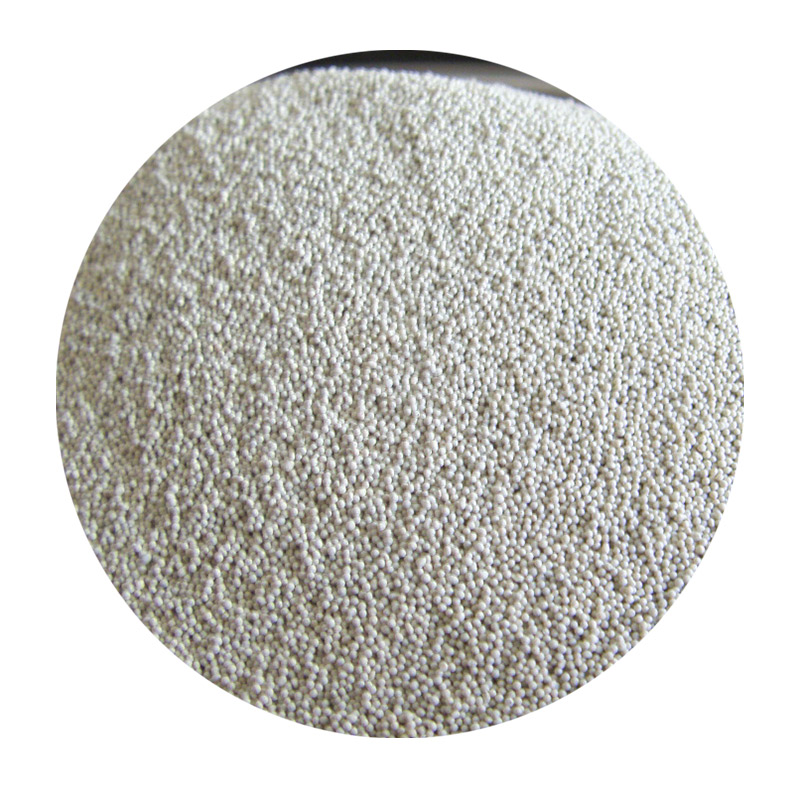

The most commonly used sand in foundries is silica sand, although other types, such as olivine sand and zircon sand, are also employed depending on the casting requirements. Each type of sand has its unique properties, which affect factors like temperature resistance, strength, and the final surface finish of the casting. For instance, silica sand is favored for its availability and cost-effectiveness, while zircon sand is known for its high melting point and excellent thermal stability.

Importance of Sand Testing

Foundry sand testing serves multiple purposes. Primarily, it ensures that the sand meets the specific requirements set forth for various casting processes. The properties of foundry sand can directly impact the fluidity of molten metal, the quality of the mold, and the eventual surface finish of the casting piece. Consequently, rigorous testing helps to identify any potential defects and mitigate risks that could lead to costly production delays or compromised final products.

Key Properties Tested

Several critical properties of foundry sand are assessed during testing

foundry sand testing

1. Grain Size The particle size distribution of the sand is crucial. Finer sands can produce smoother surfaces but may not hold their shape as well as coarser sands. Ensuring the correct grain size ranges is vital for achieving the desired balance between strength and finish.

2. Moisture Content The moisture level in sand affects the molding process. Excess moisture can lead to mold burning and dimensional inaccuracies, while insufficient moisture can cause dry sands that do not adequately bond. Testing for moisture content is essential for optimizing the molding process.

3. Compactability This property indicates the sand's ability to hold its shape under pressure. Proper compactability contributes to the strength of the mold and reduces the likelihood of mold collapse during pouring of the molten metal.

4. Permeability Permeability refers to the sand’s ability to allow gases to escape. This property is critical during the casting process, as trapped gases can lead to defects in the casting. Testing ensures that sand has appropriate permeability for specific applications.

5. Binding Properties Some foundries utilize additives to enhance the bonding properties of the sand. Testing ensures that these additives perform as intended and do not adversely affect the casting quality.

Conclusion

In summary, foundry sand testing is a fundamental aspect of metal casting that cannot be overlooked. By examining the critical properties of foundry sand, manufacturers can ensure consistent quality in their casting processes, leading to high-quality finished products that meet industry standards. The investment in thorough sand testing ultimately saves time and resources, preventing defects that can arise from using sub-par materials. As the industry evolves, advancements in sand testing methodologies will continue to play a vital role in optimizing the casting process, ensuring that foundries remain competitive in a demanding market.

Post time:Jul . 25, 2024 14:08

Next:The History and Evolution of Sand Casting Techniques Throughout the Centuries