The Art of Sanding Cast Iron Techniques and Tips for a Smooth Finish

Cast iron has long been celebrated for its durability and heat retention properties, making it a staple in cookware, machinery, and various industrial applications. However, one often overlooked aspect of working with cast iron is the process of sanding, which is essential for achieving a smooth and aesthetically pleasing finish. Whether you’re restoring a vintage skillet, smoothing out rough edges on a machine part, or prepping a surface for painting, sanding cast iron requires a specific approach to ensure optimal results.

Why Sand Cast Iron?

Sanding cast iron serves multiple purposes. First, it removes surface imperfections that can arise from casting. These imperfections can include rough spots, rust, and old paint. By sanding the surface, you not only improve the appearance but also create a better foundation for any further treatment, such as seasoning cookware or applying protective coatings.

Moreover, sanding enhances the surface's texture, making it more suitable for various applications. For instance, a well-sanded cast iron skillet can improve its non-stick qualities when seasoned, ensuring that food releases easily and the cookware lasts longer.

Choosing the Right Tools

When it comes to sanding cast iron, selecting the proper tools is crucial. Start with a good-quality sanding block, which provides a stable surface for even pressure distribution. For heavier rust or scale, consider using a power sander equipped with coarse grit sandpaper (40 to 80 grit). As you progress and the surface becomes smoother, you can switch to finer grits (100 to 220 grit) for a polished finish.

Additionally, hand tools such as metal files and scrapers can be invaluable for reaching tight areas or removing specific blemishes. For intricate work, particularly on cookware, wire brushes can be used to eliminate rust while preserving the integrity of the iron.

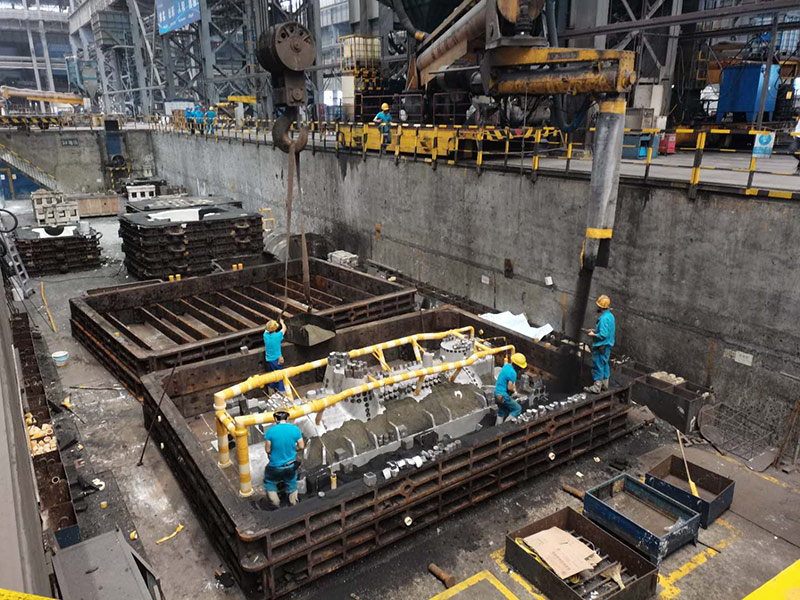

cast iron sanding

Sanding Techniques

The key to effective sanding lies in technique. Begin by assessing the surface condition of the cast iron item. If it’s heavily corroded or pitted, start with coarse sandpaper, gently working the tool in a circular motion to avoid creating flat spots. Ensure that you apply even pressure and frequently check your progress to avoid removing too much material.

As you move to finer grits, switch to long, even strokes along the casting's natural lines. This approach will help maintain the contours of the piece while providing a consistent finish. Pay special attention to corners and edges, as these areas are prone to wear and require careful handling.

It’s also important to periodically clean the surface while sanding. Cast iron dust can accumulate, obstructing your view of the surface and clogging the sandpaper. A simple brush-off or wipe with a damp cloth can make a significant difference in your sanding efficiency.

Protecting Your Work

After achieving the desired finish, it’s crucial to protect your work. For cookware, seasoning with oil is vital, as it forms a protective layer that prevents rust and enhances the non-stick surface. For industrial pieces or tools, consider applying a rust-inhibiting primer or paint to prevent corrosion.

Conclusion

Sanding cast iron might seem like a daunting task, but with the right tools, techniques, and preparation, it can be a rewarding process that enhances both the function and appearance of your cast iron items. Whether you’re a seasoned metalworker or an enthusiastic home cook, mastering the art of sanding cast iron will pay dividends in the longevity and usability of your cast iron pieces. With a little patience and skill, you can transform rough, neglected surfaces into smooth works of art.

Post time:Jul . 25, 2024 14:21

Next:Finding Quality Casting Sand Suppliers for Your Industrial Needs and Projects