Company Profile

In 2014, relying on the advantages of raw material resources and the heritage of generations of ceramic technology, shenghuoxinke took the lead in developing green, environmental friendly and high-performance "Kester ceramsite sand" applied to high-end casting industry through careful design, production verification and continuous optimization and adjustment. Its comprehensive performance is better than that of molten ceramic sand, chromite ore sand, zircon sand and silica sand. It has been widely used in the production of cast steel, cast iron, cast copper, cast aluminum and other materials, including hot core box, cold core box, 3D printing, resin sand, EPC and other molding processes.

Shenghuoxinke has 2 ceramsite sand production lines, with an annual output of 200000 tons; It has 36 experts and technicians, accounting for more than 20% of the total number of enterprises. The company has 15 independent intellectual property rights and 11 national invention patents, and has passed ISO9001 and ISO14001 system certification. It is a national high-tech enterprise.

Product Introduction

Performance characteristics

The performance advantages of KAIST sintered ceramsite sand for shenghuoxinke casting are as follows:

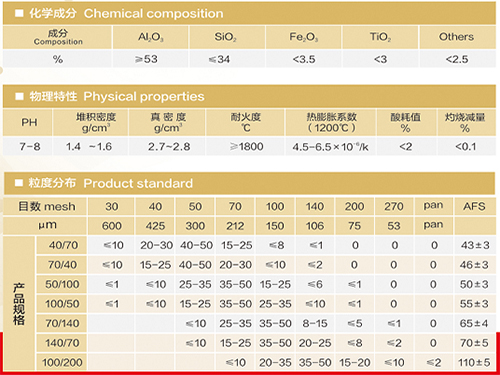

● high fire resistance, > 1800 ℃, reducing the defect rate of sand sticking, sintering, ripple and other defects of castings.

● low thermal expansion rate can greatly reduce casting defects and improve dimensional accuracy of castings;

● low angle coefficient and round grain shape, which can effectively improve the air permeability and surface accuracy of castings.

● excellent regeneration performance, mechanical and thermal regeneration can be used, the regeneration recovery rate can reach more than 98%, and the regeneration times can reach more than 100 times, so as to reduce the supplement of new sand and the emission of solid waste.

● low bulk density, 1.4-1.6g/cm3. Same weight, Kester ® Ceramsite sand can produce 29% more volume of sand core sand mold than molten ceramic sand and 80% more volume of sand core sand mold than chromite sand, so as to reduce the manufacturing cost of enterprises.

● neutral materials, strong resin affinity, and acid-base resins are available;

● good collapsibility, high casting cleaning efficiency and low cost;

● save coating. For small castings, sand cores can not be painted;

● customized and customized production; 200000 tons of production capacity to achieve stable batch supply;

● cost advantage: the cost of molding materials for long-term use is lower than that of silica sand, etc.

480h 70 Hz continuous grinding ceramsite sand

Ceramsite sand after chilling at 1300 ℃

Kester sintered ceramsite sand has the best collapsibility

Product Application

Shenghuo Xinke KAIST ceramsite sand is now widely used in film coated sand molding process, cold core box molding process, 3D printing, resin sand molding process, EPC molding process, etc., which can effectively reduce the resin addition by 30% - 50%, avoid or reduce the use of coating, improve the casting yield and surface accuracy, the regeneration rate can reach more than 99%, and reduce the enterprise production cost by more than 30%, Reduce the discharge of solid waste and realize green casting.

Application of coated sand

Application of coated sand

Cold core box application

Cold core box application

3D printing application

3D printing application

Resin sand application

Resin sand application

EPC application

EPC application

Post time: Dec-13-2021

This is the last article