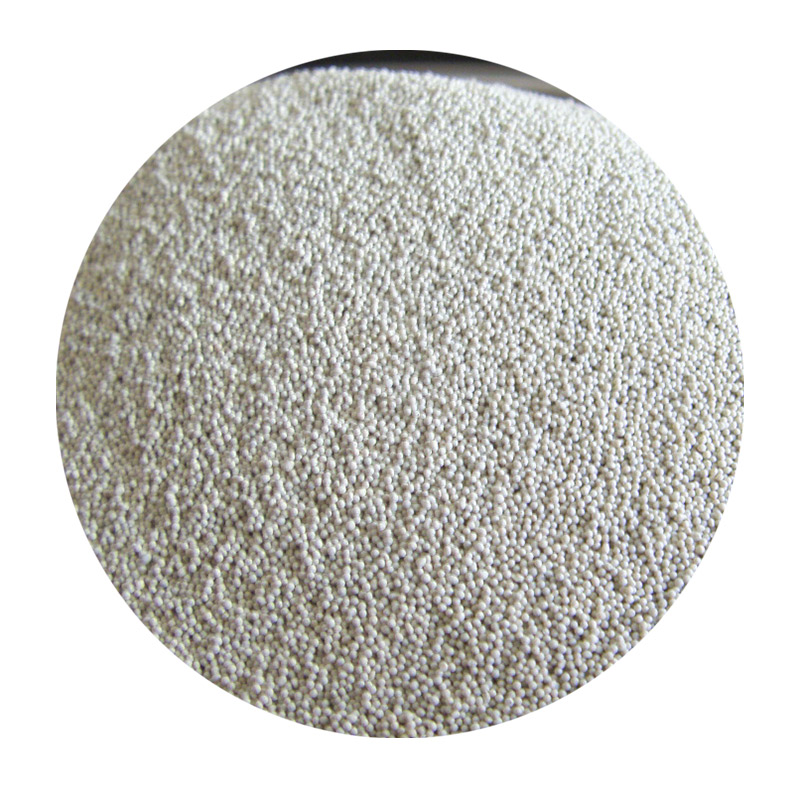

Sand casting is especially valued for its flexibility. It easily accommodates intricate designs and can handle both small and large batch productions. The adaptability doesn’t compromise its ability to deliver high-quality, durable products. However, challenges such as ensuring dimensional accuracy and surface finish require specialized knowledge and ongoing innovation in materials and techniques. Experts in sand casting continually explore enhancements to sand compositions and casting methods. Developments in binders and sand additives have enhanced mold integrity, improving overall product quality. Additionally, advancements in simulation and modeling software have revolutionized the prototyping phase, enabling more precise predictions of casting results and facilitating design improvements before committing to production. Trustworthiness in sand casting is built on years of consistent, reliable product outcomes and the expertise of skilled artisans who understand the intricate balance of art and science involved. Clients depend on expertly executed sand casting for products ranging from everyday tools to critical aerospace components. The process is backed by stringent quality controls and compliance with industry standards, ensuring clients receive applications that meet their exact specifications. In conclusion, the sand casting metal process remains a vital player in the production of metal goods. With advancements in technology and materials, this ancient method of manufacturing is continually being refined, presenting an appealing combination of tradition and innovation. It provides manufacturers the ability to produce complex and detailed metal parts with relative ease, reliability, and cost-efficiency, proving its indispensable role in the modern industrial economy. Post time:febr . 15, 2025 11:50

Next:sand casting mass production