- Neeg African

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Tuam Tshoj

- Tuam Tshoj (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Lus Askiv

- Esperanto

- Estonian

- Finnish

- Fabkis

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- haus

- hawaiian

- Hebrew

- Tsis yog

- Miao

- Hungarian

- Icelandic

- ib igbo

- Indonesian

- irish

- Italian

- Nyiv

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandan

- Kauslim

- Kurdish

- Kyrgyz

- TB

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Lavxias

- Samoan

- Scottish Gaelic

- Serbian

- Lus Askiv

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thaib

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Nyab Laj

- Welsh

- Pab

- Yiddish

- Yoruba

- Zulu

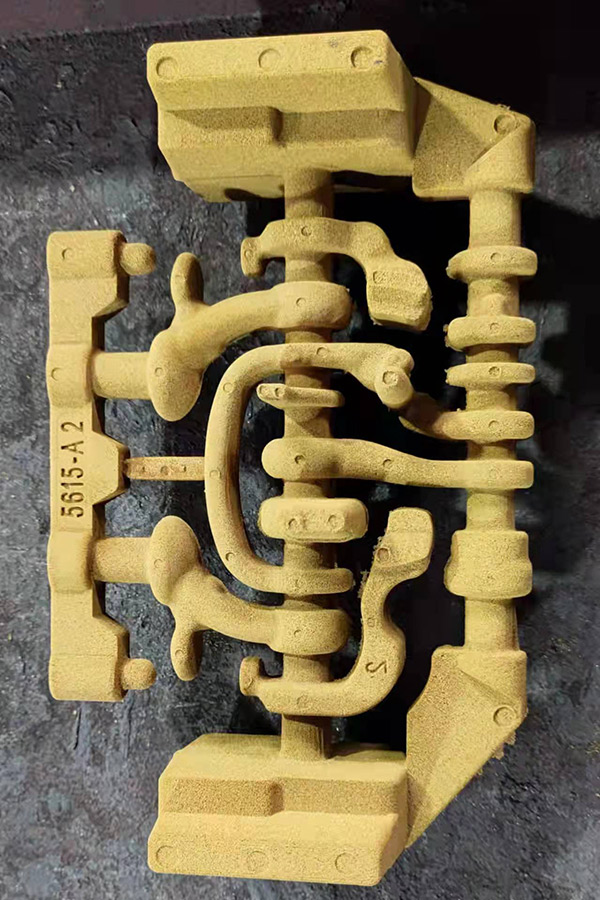

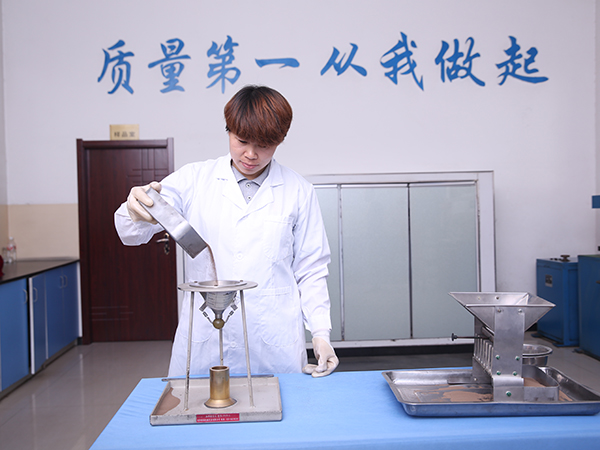

Sintered ceramic xuab zeb ua nyob rau hauv Suav teb tib yam nrog Cerabeads AFS 60

| Main Chemical Component | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Grain Shape | kheej kheej |

| Angular Coefficient | ≤1.1 |

| Particle Size | 45μm -2000μm |

| Refractoriness | ≥1800℃ |

| Kev ceev ceev | 1.45-1.6 g / cm3 |

| Thermal Expansion (RT-1200 ℃) | 4.5-6.5x10-6/k |

| Xim | Xuab zeb |

| PH | 6.6-7.3 |

| Mineralogical Composition | Mos + Corundum |

| Acid Nqi | <1 ml/50g |

| LOI | ± 0.1% |

Qhov zoo

● Sintered Ceramic xuab zeb muab lub neej ua haujlwm ntev dua thiab txo cov xuab zeb siv nyiaj

● Sintered Ceramic xuab zeb spherical zoo piv nrog angular zoo li cov nplej pub kom yooj yim sib cais los ntawm cov khoom cam khwb cia thiab txhim kho collapsibility uas ua rau qis qis thiab casting efficiency.

● Sintered Ceramic xuab zeb muaj ntau tus nqi txuag piv nrog Zircon, Chromite, Dub ceramic xuab zeb, Naigai cerabeads xuab zeb.

● Kev nyab xeeb rau ib puag ncig piv nrog Silica (silicosis) xuab zeb.

● Tsawg thermal expansion thiab thermal conductivity. Casting qhov ntev yog qhov tseeb dua thiab qis conductivity muab pwm ua haujlwm zoo dua.

● Yuav tsum tau 30-50% tsawg resin

● Yuav siv tau los ua ib qho xuab zeb

● Muab qhov tseeb qhov tseeb ntawm lub ntiajteb txawj nqus thiab thaj chaw tshwj xeeb

● Txhim kho durability piv nrog rau lwm cov xuab zeb foundry

Daim ntawv thov

Sintered ceramic xuab zeb AFS 60 yog ib qho nrov ceramic xuab zeb particle loj, tib yam nrog Naigai cerabeads 60, nws tsuas yog siv rau coated xuab zeb, plhaub moulding xuab zeb thiab lwm yam me me steel castings, hlau castings thiab alloy castings.

Parts ntawm Particle loj Distribution

Lub particle loj tis tuaj yeem kho raws li koj xav tau.

|

Mesh |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | ||

| Code | 100/50 | ≤5 | 15-25 | 35-50 | 25-35 | ≤10 | ≤1 | 55±3 | ||||

| 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±3 | |||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

Cov khoom qeb