After the metal has cooled and solidified, the sand mold is broken away, revealing the raw casting. At this point, the expertise of skilled metalworkers is required to remove any excess material, often through cutting or grinding. This stage may also involve heat treatments to enhance certain properties of the stainless steel, such as ductility or hardness. Quality control is a crucial phase in the sand casting process, reflecting a commitment to trustworthiness and reliability. Each casting undergoes rigorous inspections to identify any internal defects or discrepancies with the original design specifications. Non-destructive testing techniques such as X-ray or ultrasonic analysis are commonly employed to ensure the casting's integrity, particularly for critical applications in aerospace or medical devices. One of the distinctive advantages of sand casting stainless steel lies in its versatility. This process accommodates a wide range of sizes and complexities without exorbitant costs, unlike other casting methodologies that might require expensive molds or intricate tooling. Furthermore, stainless steel stands out for its exceptional mechanical properties, including corrosion resistance, tensile strength, and aesthetics, making it ideal for both functional and decorative applications. As industries strive towards sustainability, sand casting stainless steel offers pathways for eco-friendly practices. The sand used in the casting process can be reclaimed and recycled, reducing waste and conserving resources. Furthermore, the durability and long service life of stainless steel components ensure that they remain an environmentally sound choice for manufacturers seeking to reduce their carbon footprint without compromising on quality. Those engaging in sand casting stainless steel must possess a profound understanding of both metallurgical principles and casting dynamics. Continuous innovation in sand casting techniques and materials science ensures that this traditional process can meet the modern demands of precision, efficiency, and environmental responsibility. For companies seeking components that offer both performance and longevity, sand casting in stainless steel represents a fusion of historical craftsmanship and future-ready technology. Post time:የካቲ . 12, 2025 17:32

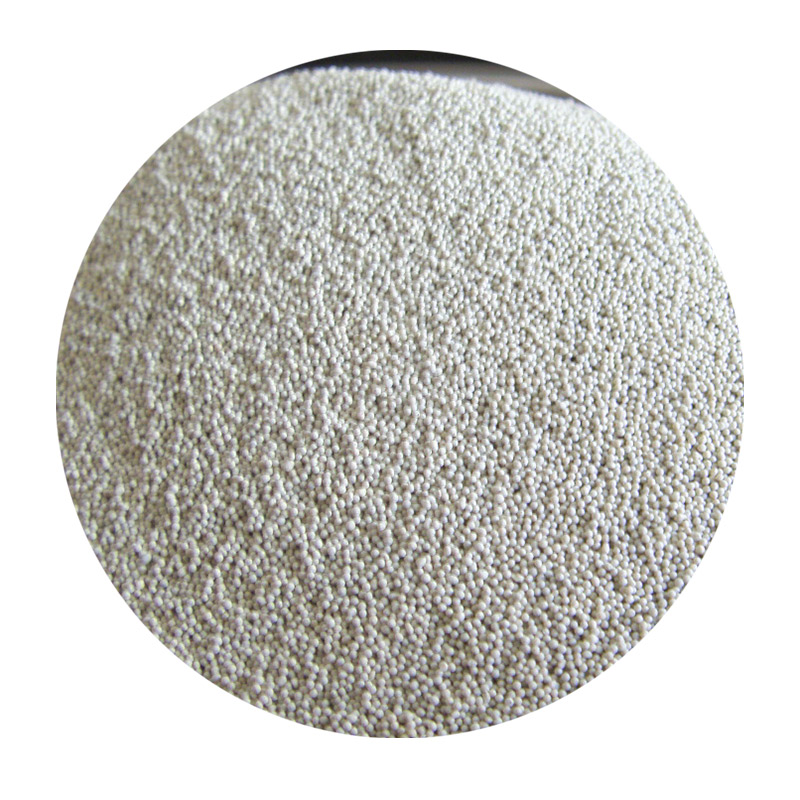

Next:Sintered ceramic sand for foundry with cold core box