The Importance of Resin Coated Sand in Industrial Applications

Resin coated sand (RCS) is a revolutionary material widely used in the foundry and manufacturing industries. It enhances the casting process by providing superior quality, strength, and precision in the final product. This article explores the significance of resin coated sand plants, their operational methodologies, and the benefits they bring to industrial applications.

What is Resin Coated Sand?

Resin coated sand is produced by coating silica sand with a thermosetting resin. The process involves mixing sand with resin and hardeners under controlled conditions to create grains that are firmly bonded with a durable coating. The resulting product exhibits superior thermal stability and is ideal for producing complex and intricate shapes in metal castings. The smooth surface of the grains also minimizes defects in the final cast, ensuring higher quality outputs.

Operating a Resin Coated Sand Plant

The operation of a resin coated sand plant involves several critical steps

1. Sand Selection The process begins with selecting high-quality silica sand, which acts as the primary substrate for coating.

2. Coating Process The selected sand is mixed with the chosen resin and additives, such as curing agents, in a specialized mixing unit. This stage is crucial as it determines the coating uniformity and thickness.

3. Curing Once coated, the sand must be cured to harden the resin. This step can involve heating or chemical reactions that solidify the resin and create a robust bond.

4. Quality Control Quality checks are performed to ensure that the coated sand meets specific operational requirements, such as grain size, coating uniformity, and thermal properties.

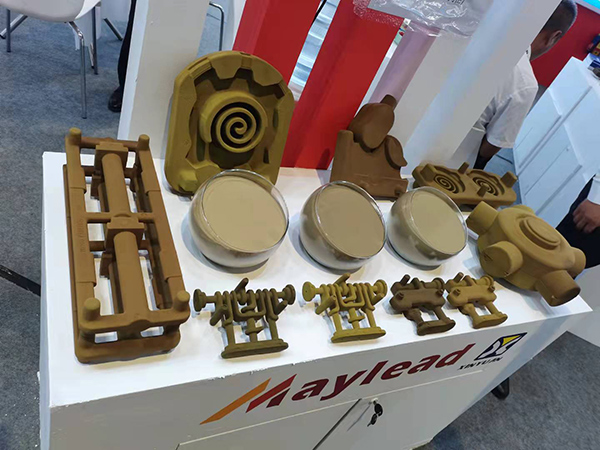

resin coated sand plant

Benefits of Using Resin Coated Sand

The use of resin coated sand offers numerous advantages over traditional molding sands

- Improved Surface Finish The resin coating provides a smooth surface for the castings, reducing the need for extensive finishing work.

- Higher Dimensional Accuracy RCS allows for greater precision in the casting process, which is crucial for components that require tight tolerances.

- Enhanced Strength and Durability The hardened resin gives the sand greater strength, allowing for the production of complex designs that can withstand the rigors of heavy manufacturing.

- Reduced Defects The properties of resin coated sand minimize issues such as sand adhesion, gas porosity, and dimensional distortion, resulting in higher quality castings.

- Environmental Considerations Many modern resin coated sand plants utilize eco-friendly resins and processes that reduce emissions and waste, making them more sustainable in the long run.

Conclusion

As industries continue to evolve and demand higher quality products, resin coated sand plants play a vital role in meeting these challenges. By leveraging advanced materials science and efficient production techniques, RCS not only enhances the casting process but also supports the production of high-performing components across various sectors. With a growing emphasis on quality and sustainability, the future of resin coated sand appears brighter than ever.

Post time:መስከ . 01, 2024 08:05

Next:3d sand casting