The Importance of Ceramsite Foundry Sand in Modern Casting Processes

In the ever-evolving world of manufacturing, the quest for high-quality materials that enhance production efficiency and final product integrity remains paramount. Among the many innovations in materials science, ceramsite foundry sand has emerged as a significant player, offering numerous advantages over traditional sand types in casting applications.

What is Ceramsite Foundry Sand?

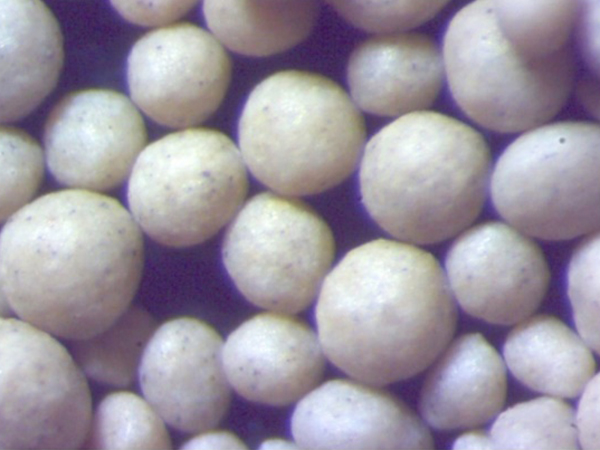

Ceramsite foundry sand is a type of engineered sand produced from natural clay minerals that are subjected to high-temperature treatment, typically around 1200°C to 1500°C. This process creates lightweight, spherical granules that exhibit excellent thermal and mechanical properties. The result is a material that is not only durable but also resistant to thermal shock, making it ideal for the demanding conditions of metal casting.

Benefits of Ceramsite Foundry Sand

1. Enhanced Casting Quality One of the primary advantages of ceramsite foundry sand is its ability to improve the surface finish of cast products. The spherical shape of the granules allows for a smoother mold and reduces the formation of defects such as sand inclusions, which can compromise product integrity.

2. Reduced Environmental Impact The use of ceramsite foundry sand can also contribute to more environmentally friendly casting practices. Because it is produced from natural materials and can often be recycled more effectively than traditional sands, it helps minimize waste. Additionally, its durability decreases the frequency of sand replacement, further lowering the environmental footprint of casting operations.

3. High Thermal Stability Ceramsite sand is exceptionally resistant to high temperatures, which is a crucial property when dealing with molten metals. This thermal stability ensures that the sand maintains its shape and integrity during the casting process, reducing the likelihood of sand-related defects and enhancing overall product quality.

ceramsite foundry sand

4. Weight Reduction The lightweight nature of ceramsite foundry sand can lead to lower transportation and handling costs. When used in large quantities, the reduction in weight can result in significant savings, particularly in operations that rely on the movement of heavy materials.

5. Improved Flowability and Fillability The spherical granules of ceramsite sand allow for better flowability, making it easier to fill molds and achieve intricate designs. This characteristic is particularly beneficial in complex casting processes where precision is critical.

Applications of Ceramsite Foundry Sand

Ceramsite foundry sand is used across various industries, including automotive, aerospace, and heavy machinery. In the automotive sector, for instance, it plays a vital role in the production of engine components and transmission housings, where the need for precision and structural integrity is paramount. Similarly, in aerospace applications, where weight and strength are critical, ceramsite sand facilitates the creation of lightweight yet durable components.

Future Trends

As the manufacturing industry continues to innovate, the demand for advanced materials like ceramsite foundry sand is expected to grow. Research into further enhancing its properties and expanding its applications is ongoing. Additionally, as sustainability becomes an increasing priority for manufacturers, the adoption of ceramsite sand may accelerate due to its environmentally friendly attributes.

Conclusion

Ceramsite foundry sand represents a significant advancement in casting technology, combining performance and sustainability in a single material. Its numerous benefits—from enhanced casting quality and reduced environmental impact to improved handling characteristics—position it as a leading choice for modern foundries. As industries strive for greater efficiency and product quality, the importance of materials like ceramsite foundry sand will undoubtedly continue to rise, shaping the future of manufacturing processes for years to come.

Post time:11 月 . 08, 2024 19:39

Next:sand 3d