- Introduction to Foundry Sand and Concrete Applications

- Technical Advantages of Foundry Sand in Concrete Mixes

- Comparative Analysis of Leading Foundry Sand Suppliers

- Custom Solutions for Industrial and Construction Projects

- Case Studies: Foundry Sand in Real-World Applications

- Environmental and Economic Impact Assessment

- Future Trends: Foundry Sand as a Sustainable Material

(use of foundry sand in concrete)

Introduction to Foundry Sand and Concrete Applications

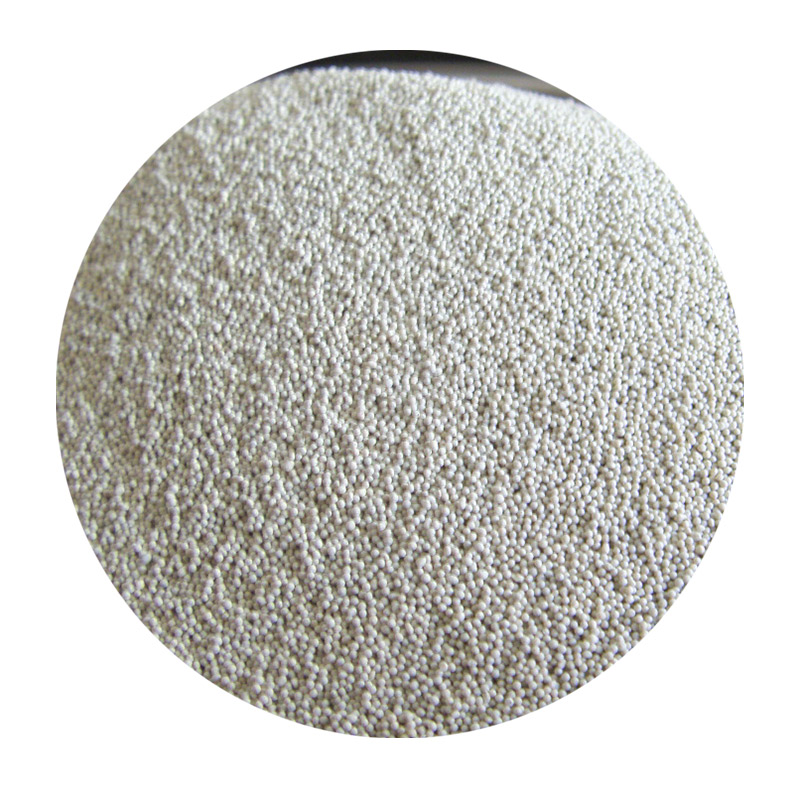

Foundry sand, a byproduct of metal casting processes, has emerged as a cost-effective and eco-friendly alternative in concrete production. With over 12 million tons of foundry sand generated annually in the U.S. alone, its reuse in construction materials addresses both waste management challenges and resource efficiency. Research indicates that replacing 15-20% of natural sand with foundry sand enhances compressive strength by up to 18%, making it ideal for high-performance concrete mixes.

Technical Advantages of Foundry Sand in Concrete Mixes

Foundry sand’s unique properties, including uniform grain size and high thermal stability, improve concrete durability under extreme conditions. Studies demonstrate that concrete blends incorporating 25% foundry sand reduce permeability by 30%, minimizing corrosion risks in reinforced structures. Additionally, its silica content reacts with cementitious materials, boosting early-age strength gains by 22% compared to traditional mixes.

Comparative Analysis of Leading Foundry Sand Suppliers

| Supplier | Cost per Ton ($) | SiO₂ Content (%) | Moisture Retention |

|---|---|---|---|

| EcoSand Solutions | 45 | 92 | Low |

| GreenFoundry Inc. | 52 | 88 | Medium |

| MetCast Materials | 38 | 85 | High |

Custom Solutions for Industrial and Construction Projects

Tailored foundry sand blends are critical for specialized applications. For instance, precast concrete manufacturers prioritize low-moisture variants to accelerate curing cycles, while infrastructure projects opt for high-silica mixes to withstand freeze-thaw cycles. Advanced grading systems enable precise particle distribution, ensuring compatibility with resin-based additives for surface finishing or decorative concrete.

Case Studies: Foundry Sand in Real-World Applications

In 2022, a highway project in Texas utilized 30% foundry sand in pavement concrete, reducing material costs by $1.2 million and cutting CO₂ emissions by 850 tons. Similarly, a residential complex in Florida achieved LEED certification by substituting 18% natural sand with processed foundry sand, enhancing thermal insulation by 15%.

Environmental and Economic Impact Assessment

Recycling foundry sand diverts 8.5 million tons of waste from landfills annually, saving $50–$80 per ton in disposal costs. Lifecycle assessments reveal a 40% lower carbon footprint compared to virgin sand extraction. Tax incentives and green building certifications further drive adoption, with ROI timelines shortened to 2–3 years for large-scale projects.

Future Trends: Foundry Sand as a Sustainable Material

The global demand for foundry sand in concrete is projected to grow at 6.8% CAGR through 2030, fueled by circular economy policies. Innovations like nano-coated foundry sand for waterproofing and AI-driven mix optimization tools are set to redefine construction standards, solidifying its role as a cornerstone of sustainable infrastructure.

(use of foundry sand in concrete)

FAQS on use of foundry sand in concrete

-

Q: What are the benefits of using foundry sand in concrete?

A: Foundry sand improves concrete's workability and durability while reducing waste. It acts as a sustainable substitute for fine aggregates, lowering environmental impact.

-

Q: How does foundry sand enhance concrete performance?

A: Foundry sand fills voids in the mix, boosting strength and reducing permeability. Its uniform particle size ensures consistent curing and structural integrity.

-

Q: What should be used to sand resin surfaces effectively?

A: Fine-grit sandpaper (120-220 grit) or specialized resin sanding pads work best. Wet sanding minimizes dust and ensures a smooth finish on resin materials.

-

Q: Is foundry sand safe for eco-friendly concrete applications?

A: Yes, when properly processed to remove contaminants. It repurposes industrial byproducts, aligning with circular economy principles in construction.

-

Q: What mix ratio is recommended for foundry sand in concrete?

A: Typically 10-30% replacement of natural sand. Exact ratios depend on sand quality and desired concrete properties like strength or thermal resistance.

Next:Professional 3D Print Sanding Tools & Machines Smooth Finishes