Can You Sand 3D Prints? A Comprehensive Guide

3D printing has revolutionized the way we create objects, allowing for unprecedented design flexibility and customization. However, one common question that many enthusiasts and professionals encounter is, “Can you sand 3D prints?” The answer is yes, and in this article, we will explore the reasons for sanding, the techniques involved, and tips to achieve the best results.

Why Sand 3D Prints?

Sanding 3D prints can serve multiple purposes. Firstly, it is often necessary for improving surface finish. Many 3D printed objects, especially those produced with Fused Deposition Modeling (FDM) printers, exhibit visible layer lines. These lines can detract from the aesthetic appeal of a finished product, making sanding a valuable step in post-processing.

Secondly, sanding can help to fix minor imperfections in the print. Sometimes, bridging or overhangs may not come out perfect due to printer limitations, and sanding smooths out these flaws for a more polished final result. Lastly, sanding can help prepare the surface for further treatments, such as painting or sealing, allowing for better adhesion of coatings and a more uniform appearance.

Techniques for Sanding 3D Prints

When it comes to sanding 3D prints, there are several techniques that can be employed, depending on the material used and the desired outcome.

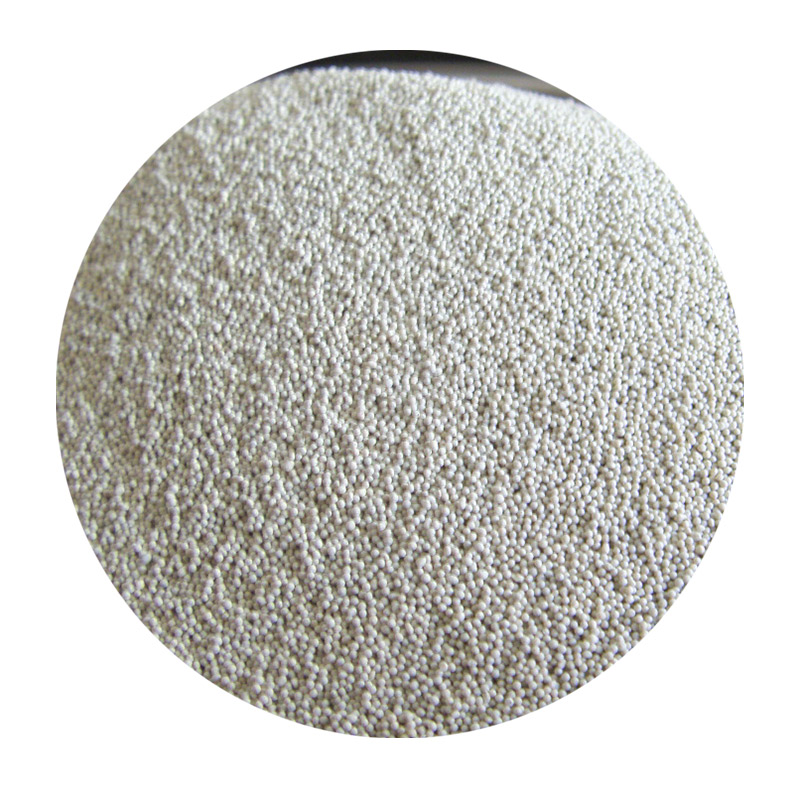

1. Start with Coarse Grit Sandpaper If the layer lines are particularly pronounced, begin with a coarse grit sandpaper (around 100-200 grit). This initial stage is aimed at removing as much material as possible and smoothing out the rough texture. Be cautious and sand evenly to avoid creating divots or uneven areas.

2. Progress to Finer Grits After achieving a smoother surface with coarse sandpaper, switch to finer grits (400, 800, and up to 2000 grit). This step is essential for refining the surface and eliminating scratches left by the coarser sandpaper. The finer the grit, the smoother the finish — but remember, it can take longer!

can you sand 3d prints

3. Wet Sanding For some materials, particularly acrylic or resin prints, wet sanding is highly effective. This method involves using water to lubricate the sandpaper, which helps achieve a smoother surface by reducing friction and the potential for dust. It also minimizes the risk of overheating the plastic during the sanding process.

4. Use a Dremel or Sander for Larger Areas For larger parts or when you're short on time, consider using a rotary tool like a Dremel with sanding attachments. This can help speed up the process significantly, but be careful, as it's easy to remove too much material.

Tips for Effective Sanding

- Test on a Sample Piece Before diving into sanding your final print, it's wise to test your techniques on a spare print or a sample of the same material. This will help you gauge how much material you can safely remove and what grit works best.

- Wear Protective Gear Sanding can produce fine dust particles, which may be harmful to inhale. Always wear a mask and safety goggles while sanding to protect yourself.

- Clean Between Grits After sanding with each grit, be sure to wipe down the print to remove any dust. This prevents larger particles from scratching the surface during subsequent sanding stages.

- Consider Coating After Sanding Once you've achieved the desired smoothness, consider applying a primer or paint that is compatible with your 3D printing material. This not only enhances aesthetics but can also protect the surface.

In conclusion, sanding is not only possible but often necessary for achieving professional-quality finishes on 3D printed objects. With the right techniques and attention to detail, you can transform your prints from utilitarian to beautifully finished pieces, enhancing both their look and feel. Whether you’re a hobbyist or a professional, mastering the art of sanding will undoubtedly elevate your 3D printing game.

Post time:Dec . 05, 2024 14:53

Next:difference between sand casting and permanent mold casting