Authoritative insights into sanding ceramics also highlight the importance of a wet sanding technique. This involves dampening the ceramic surface or sandpaper with water, which acts as a lubricant, minimizes dust production, and reduces heat from friction. This method not only protects the ceramic piece but also prolongs the life of the sandpaper, making it a favored technique among professional restorers and conservationists. Real experience suggests that safety precautions should not be overlooked. The fine dust produced from dry sanding ceramics can pose health risks if inhaled over time. Therefore, wearing a dust mask and ensuring adequate ventilation in the workspace is recommended, a practice advocated by occupational safety experts. Trustworthiness in the results comes from meticulous preparation and careful execution. Cleaning the ceramic thoroughly before sanding removes grease and debris that may mar the surface. Similarly, post-sanding, a detailed cleaning with a soft cloth and mild detergent ensures any residual dust is eliminated, revealing a pristine surface ready for subsequent treatments like glazing or painting. The culmination of these methods—formed from experience, professional practices, and expert advice—establishes a reliable foundation for sanding ceramic surfaces. Whether for aesthetic enhancement of handmade pottery or preparatory work in tile installation, mastering this craft ensures not only technical excellence but also preserves the integrity of the ceramic material. Post time:Th1 . 09, 2025 11:50

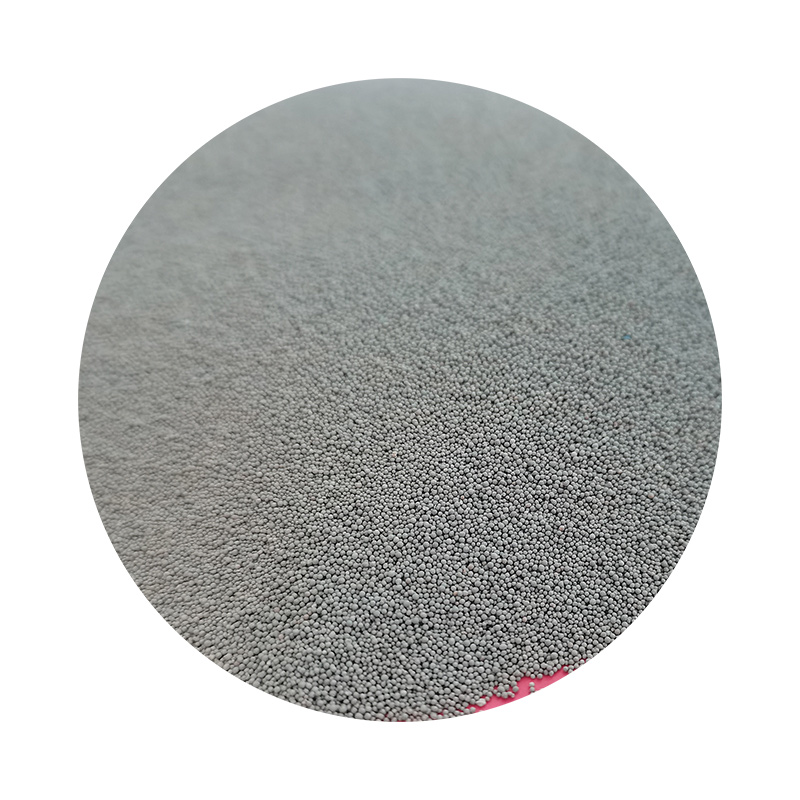

Next:Sintered ceramic sand made in China same with Cerabeads AFS 60