Is Sand Casting Sustainable?

Sand casting, one of the oldest metal-forming techniques, has been used for thousands of years in various industries, including automotive, aerospace, and construction. As the world increasingly emphasizes sustainable manufacturing practices, it is essential to assess the environmental impact of traditional methods like sand casting and explore their sustainability potential.

The Process of Sand Casting

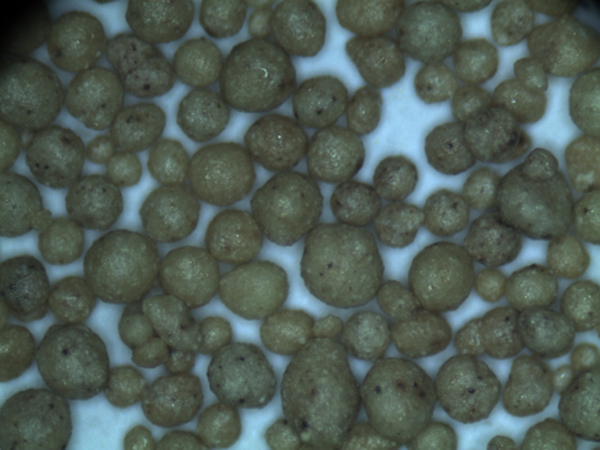

Sand casting involves creating a mold from a sand mixture that contains clay and water. The process begins with creating a pattern of the object to be cast, which is typically made of metal or plastic. The pattern is pressed into the sand to form a cavity that outlines the shape of the final product. Once the mold is prepared, molten metal is poured into the cavity and allowed to cool and solidify. After cooling, the mold is broken apart to retrieve the finished casting.

Environmental Impacts

While sand casting has its advantages, including the ability to produce complex shapes and low tooling costs, it does come with environmental implications. One of the primary concerns is the materials used in the process. Sand is abundant and can be recycled, but the addition of binders and chemical additives often raises environmental flags. Some of these additives can release harmful emissions when heated, contributing to air pollution.

Another issue arises from energy consumption. Melting metals requires significant energy, often sourced from fossil fuels, which exacerbates greenhouse gas emissions. Furthermore, sand casting can generate waste materials, including excess sand and metal scraps, which must be managed carefully to reduce landfill contributions.

The Case for Sustainability

is sand casting sustainable

Despite these challenges, there are several compelling arguments for the sustainability of sand casting. Firstly, the abundance and recyclability of sand make it an attractive option compared to other materials. Moreover, advancements in technology have led to innovations in sand casting processes, allowing for more efficient energy use and reducing wastage.

For instance, many modern sand casting operations have adopted more sustainable methods, such as thermally reclaiming used sand. This process allows manufacturers to reuse sand multiple times, significantly lowering the need for new material and minimizing waste production. Additionally, some shops are moving toward organic binders that reduce harmful emissions during the melting and casting processes, thereby contributing to improving air quality.

The rise of automation and 3D printing technologies also addresses some of the sustainability concerns. 3D printing can create molds with extreme precision, reducing material waste and the energy required during the casting process. This can potentially lead to lower carbon footprints in the manufacturing sector while preserving the benefits of traditional sand casting methods.

Economic and Social Implications

Beyond the environmental considerations, economic and social factors also weigh heavily on the sustainability debate. Sand casting remains a cost-effective method for small to medium-sized production runs, which is essential for many manufacturers who seek affordable ways to produce high-quality parts. Moreover, small foundries that utilize sand casting often play a vital role in local economies, providing jobs and promoting craftsmanship.

Supporting these local industries through sustainable practices not only helps mitigate environmental impacts but also preserves traditional skills and knowledge that are invaluable in an age increasingly dominated by automation.

Conclusion

In conclusion, while traditional sand casting presents several environmental challenges, its sustainability is supported by ongoing advancements and innovations within the industry. By optimizing processes, recycling materials, and adopting eco-friendly practices, sand casting can continue to be a viable method of production that addresses modern concerns about sustainability. Recognition of the balance between economic viability, social responsibility, and environmental stewardship will shape the future of this age-old practice in a world that demands sustainable solutions. As such, sand casting holds significant promise within the transition towards more sustainable manufacturing paradigms.

Post time:Dek . 12, 2024 11:49

Next:g2 super sand bond