Examples of Sand Casting Products

Sand casting, a versatile and widely used manufacturing process, plays a crucial role in producing a diverse array of items across various industries. This method involves creating a mold from a mixture of sand and a bonding agent and pouring molten metal into the mold to form solid products. The flexibility and cost-effectiveness of sand casting make it an attractive choice for both small-scale crafts and large industrial applications. In this article, we will explore some notable examples of sand casting products and their significance in different sectors.

1. Automotive Components

One of the most significant applications of sand casting is in the automotive industry. Many essential engine components, such as cylinder heads, engine blocks, and crankshafts, are produced using this method. For instance, the intricate designs and high strength requirements of an engine block necessitate the use of sand casting, which allows for complex shapes that would be difficult to achieve using other methods. The ability to produce large quantities of these components efficiently has made sand casting an indispensable part of automotive manufacturing.

2. Aerospace Parts

The aerospace industry demands the highest standards of precision and reliability, and sand casting meets these strict criteria for various components. Products such as structural frames, landing gear components, and turbine housings are often made using sand casting techniques. For example, the parts used in jet engines must withstand extreme temperatures and pressures, making the durability and structural integrity provided by sand casting vital for safety and performance in aerospace applications.

Beyond industrial applications, sand casting is also a favored method among artisans and sculptors to create intricate art pieces. Artists can design unique sculptures by creating custom molds, allowing for a high degree of creativity and expression. Bronze sculptures, for example, often utilize sand casting techniques, capturing fine details and textures. This artistic versatility highlights how sand casting is not only about functionality but also about aesthetic appeal in the world of art.

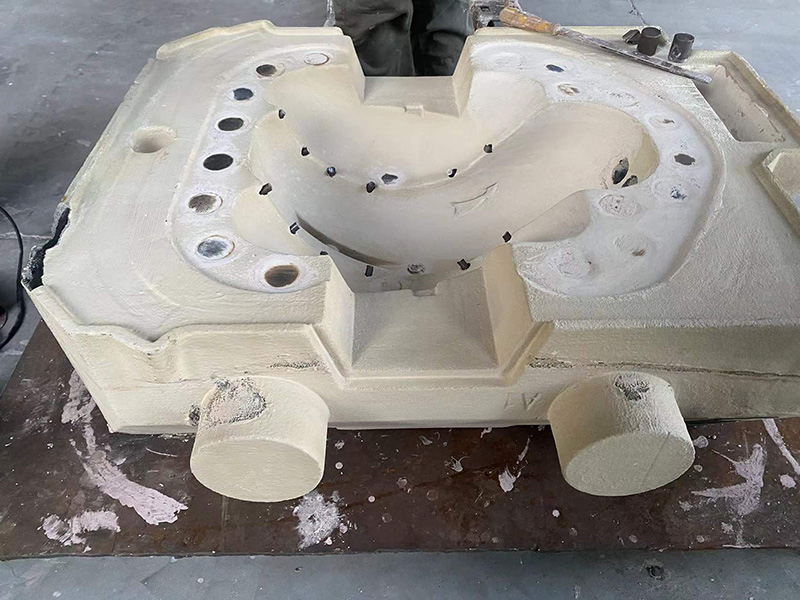

examples of sand casting products

4. Plumbing Fittings

In the plumbing industry, sand-cast products like faucets, valves, and pipes are highly prevalent. The durability and corrosion resistance of metals used in sand casting, such as bronze and brass, make them ideal for plumbing applications. These products are crucial for supplying water and distributing it throughout buildings while ensuring long-lasting performance under varying pressure and temperature conditions.

5. Decorative Items

Sand casting is also used to produce various decorative items, including garden ornaments, furniture fittings, and architectural features. These products often combine function with a beautiful design, enhancing the aesthetic quality of living spaces. For example, sand-cast iron garden benches often exhibit intricate designs that are both sturdy and visually appealing, showcasing craftsmanship that lasts for generations.

6. Construction Materials

The construction industry benefits significantly from sand casting through the production of components like brackets, beams, and other structural elements. These components must exhibit high strength and fatigue resistance, which sand casting can provide. Additionally, sand-cast products can be tailored to specific requirements, allowing builders and architects the flexibility to create innovative structures with unique designs.

Conclusion

Sand casting is an age-old process that continues to thrive in modern manufacturing, producing an extensive range of products that serve various industries. From automotive and aerospace components to artistic sculptures and practical plumbing fittings, the versatility of sand casting caters to differing needs while maintaining efficiency and cost-effectiveness. As technology advances, the techniques and materials used in sand casting will also evolve, ensuring its relevance and application in future manufacturing endeavors. Through these examples, it is clear that sand casting is more than just a method; it is a vital contributor to the creation of everyday products we rely on and appreciate in our lives.

Post time:نومبر . 08, 2024 04:50

Next:Innovative Techniques in 3D Printed Sand Casting for Advanced Manufacturing Applications