Sand Casting Technology An Overview

Sand casting, one of the oldest and most versatile metal casting methods, has been in use for thousands of years. This technique involves pouring molten metal into a sand mold to create a variety of components, from simple to highly complex designs. Its widespread application across industries—ranging from automotive and aerospace to art and jewelry—underscores its significance in modern manufacturing.

Sand Casting Technology An Overview

One of the key benefits of sand casting is its ability to produce large and complex parts that would be difficult or impractical to create using other manufacturing processes. This is particularly important in industries such as aerospace, where components must often meet stringent performance and safety standards. The flexibility of sand casting also allows for ready customization, making it an ideal choice for prototype development and small production runs.

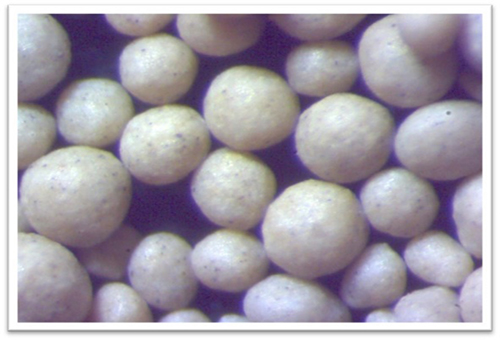

sand casting technology

While sand casting is known for its advantages, it is not without challenges. The surface finish of sand-cast parts can be coarse, and achieving tight tolerances may require additional machining. However, advancements in technology have led to innovations such as the use of resin-bonded sands and improvements in pattern-making techniques, which enhance the quality of the final products. Furthermore, the incorporation of computer-aided design (CAD) and simulation software has made it possible to optimize the casting process, reducing defects and improving efficiency.

Environmental considerations are also becoming increasingly important in the sand casting industry. Traditional sand casting methods generate considerable waste and consume energy. However, many manufacturers are now adopting greener practices, such as recycling sand and utilizing more sustainable materials in their operations. These efforts not only contribute to a reduced ecological footprint but also align with global initiatives aimed at promoting sustainable manufacturing.

In conclusion, sand casting technology remains a foundational technique in metal fabrication due to its versatility, efficiency, and cost-effectiveness. Its ability to accommodate a wide range of materials, designs, and production scales continues to make it a preferred choice across multiple industries. As technology advances and environmental challenges grow, the sand casting industry is likely to evolve further, incorporating innovative practices that enhance its sustainability and efficiency. This enduring method not only pays homage to traditional craftsmanship but also paves the way for a future where quality and sustainability coexist.

Post time:Жов . 15, 2024 08:09

Next:Innovative Uses of Resin Mixed with Sand for Construction and Art Projects