Types of Sand Used in Foundry

The foundry industry plays a crucial role in manufacturing, particularly in casting metal parts. One of the most important materials used in this process is sand. Sand serves as the primary molding material due to its favorable properties, such as heat resistance, strength, and ability to be easily shaped. Various types of sand are used in the foundry, each possessing unique characteristics that suitable for different casting applications. This article explores the most common types of sand used in foundry operations, their properties, and their specific uses.

1. Silica Sand

Silica sand is the most widely used sand in foundries. Composed mainly of silicon dioxide (SiO₂), this type of sand is abundant and easily accessible. Silica sand is favored for its high melting point, which allows it to withstand the extreme temperatures encountered during metal casting. It can effectively form mold cavities and is known for its excellent permeability, permitting gases to escape during the pouring of molten metal. However, silica sand can present health risks due to the potential for crystalline silica dust to be inhaled, leading to respiratory issues. As such, safety precautions are necessary when handling this material.

Chromite sand, derived from chromite ore, is another specialized type of sand used in foundries. It boasts superior thermal stability and a high melting point, making it particularly beneficial for casting high-temperature metals like steel. Chromite sand is less prone to deformation under extreme heat compared to silica sand, which enhances the quality of the final castings. Additionally, it has excellent resistance to metal penetration, imparting high dimensional accuracy. However, chromite sand is more expensive and less readily available than silica sand, limiting its use primarily to high-value applications.

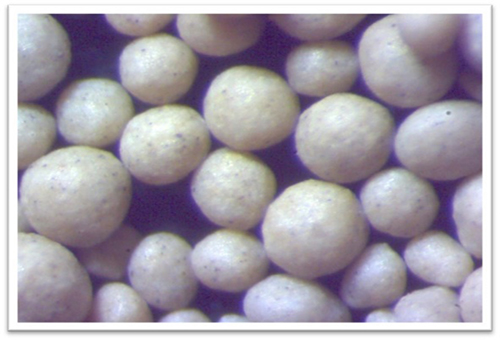

3. Green Sand

types of sand used in foundry

Green sand is a mixture of silica sand, clay, and water, used extensively in foundries for its ability to form sturdy molds. The clay content in green sand acts as a binding agent, which allows the sand grains to stick together when wet. This mixture is easy to mold and can be reused several times, making it a cost-effective choice for many foundries. Green sand molds exhibit good strength and permeability, aiding in gas escape during the pouring process. The term green refers to the fact that the mold is wet, as opposed to its color. This sand is particularly popular for the casting of ferrous metals.

4. Resin-Bonded Sand

Resin-bonded sand is created by mixing fine silica sand with a resin binder and a hardener. This combination leads to a mold that is resistant to collapse and deformation, even under high temperatures. Resin-bonded sand offers excellent surface finish and dimensional accuracy, making it an ideal choice for precision casting. Furthermore, the molds can be produced in a short duration, which enhances productivity in foundry operations. However, the resin materials can be more expensive than traditional sand and require proper ventilation due to fumes released during the curing process.

5. Cores Sand

Cores are used in conjunction with molds to create internal passages in castings. Core sand is usually composed of a sand mixture with a bonding agent such as oil or resin, giving it special properties to withstand the pouring of molten metal. Cores can be made using various materials, but the most common are sodium silicate and phenolic resin. The choice of core sand depends on the specific casting requirements and desired properties.

Conclusion

The selection of sand types in foundry operations directly impacts the quality, efficiency, and cost-effectiveness of the casting process. Each type of sand—be it silica, chromite, green, resin-bonded, or core sand—offers unique advantages tailored to specific applications in metal casting. As the foundry industry continues to innovate with advanced materials and technologies, understanding the properties and uses of different sands remains essential for engineers and manufacturers aiming for excellence in their cast products. The choice of sand not only reflects on the final product but also on the sustainability and economic viability of the foundry processes.

Post time:دېكابىر . 25, 2024 09:53

Next:sand 3d printing