Is Sand Casting Expensive?

Sand casting, a traditional metal casting process, has been a cornerstone of the manufacturing industry for centuries. It involves creating molds from sand to hold molten metal, allowing for the production of intricate parts and shapes. Despite its long-standing history and versatility, many people wonder whether sand casting is an expensive process. To address this question, we need to explore various factors, including material costs, tooling expenses, production volume, and overall efficiency.

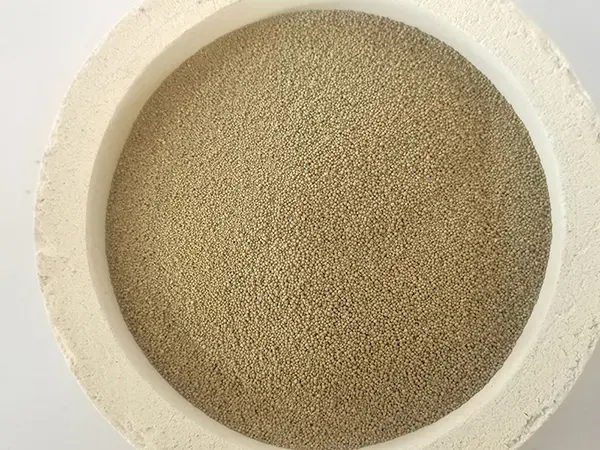

Material Costs

The primary materials required for sand casting are sand and the metal to be cast. Generally, silica sand, which is abundant and inexpensive, serves as the primary molding material. This makes the initial material cost relatively low compared to other casting processes such as investment or die casting. However, the type of metal used can significantly affect overall expenses. Cast irons and aluminum are typically more economical than high-value materials like titanium or certain alloys. Therefore, the choice of metal plays a crucial role in determining the overall cost of sand casting projects.

Tooling Expenses

Tooling refers to the creation of the molds into which the molten metal is poured. In sand casting, the tooling costs are generally lower than in other casting methods because sand molds are often made from patterns that can be reused multiple times. However, the initial pattern and equipment required to create the molds can incur substantial expenses, particularly for complex geometries. If a company needs custom patterns, the design and production of these tools could impact the overall cost. Nevertheless, the advantage of sand casting is the flexibility it provides in terms of mold design, allowing manufacturers to adapt quickly to different project requirements without significantly increasing costs.

is sand casting expensive

Production Volume

The economics of sand casting are also heavily influenced by production volume. For low to medium-volume production runs, sand casting often proves to be cost-effective. The process allows for rapid production and the ability to alter designs as necessary, which is advantageous for prototyping and small batches. However, for high-volume productions, other casting methods like die casting may become more economical due to their efficiencies. This transition primarily occurs because the costs associated with creating patterns and molds become a smaller fraction of the overall expenses as the number of parts increases.

Overall Efficiency

Another important aspect to consider is the overall efficiency of the sand casting process. While it may be seen as labor-intensive and time-consuming, advancements in technology and automation have improved the efficiency of sand casting significantly in recent years. Automated sand molding machines and improved sand recycling techniques have reduced labor costs and material waste, making the process more environmentally friendly while also lowering expenses.

Conclusion

In conclusion, whether sand casting is expensive or not is contingent upon several variables, including material selection, tooling costs, production volume, and process efficiency. For smaller production runs and specific applications, sand casting can be a cost-effective solution. Conversely, for large-scale production needs, other casting methods might offer significant cost advantages. Understanding these factors allows manufacturers to make informed decisions when selecting the appropriate casting process for their projects. Ultimately, sand casting remains a vital and versatile method in the production of metal parts, striking a balance between cost and flexibility in manufacturing.

Post time:ئۆكتەبىر . 10, 2024 15:12

Next:sand casting foundry process