The Versatile Applications of Cerabeads Sand

Cerabeads sand, a high-performance material known for its unique properties, has been gaining attention in various fields, particularly in industrial applications. Developed through innovative processes, cerabeads are essentially hollow ceramic spheres that offer a range of advantages, making them suitable for a variety of uses.

One of the most remarkable attributes of cerabeads sand is its exceptional thermal resistance. Capable of withstanding high temperatures without degrading, cerabeads are often employed in the foundry industry. In metal casting, for instance, they serve as a superior alternative to traditional sand. The uniform particle size of cerabeads allows for better mold filling and reduces the chances of defects in the final casting product. Furthermore, their thermal stability minimizes the risk of cracking during the cooling process, resulting in higher-quality castings with improved mechanical properties.

In addition to foundry applications, cerabeads sand is increasingly being used in the field of construction. As a lightweight aggregate, cerabeads can enhance the performance of concrete mixtures. Their low density reduces the weight of the final product, making it easier to transport and handle. Additionally, when incorporated into concrete, cerabeads contribute to improved insulation properties. This is particularly beneficial in energy-efficient building designs, where maintaining stable indoor temperatures is a priority. The use of cerabeads not only enhances thermal performance but also helps in achieving lighter and more sustainable construction materials.

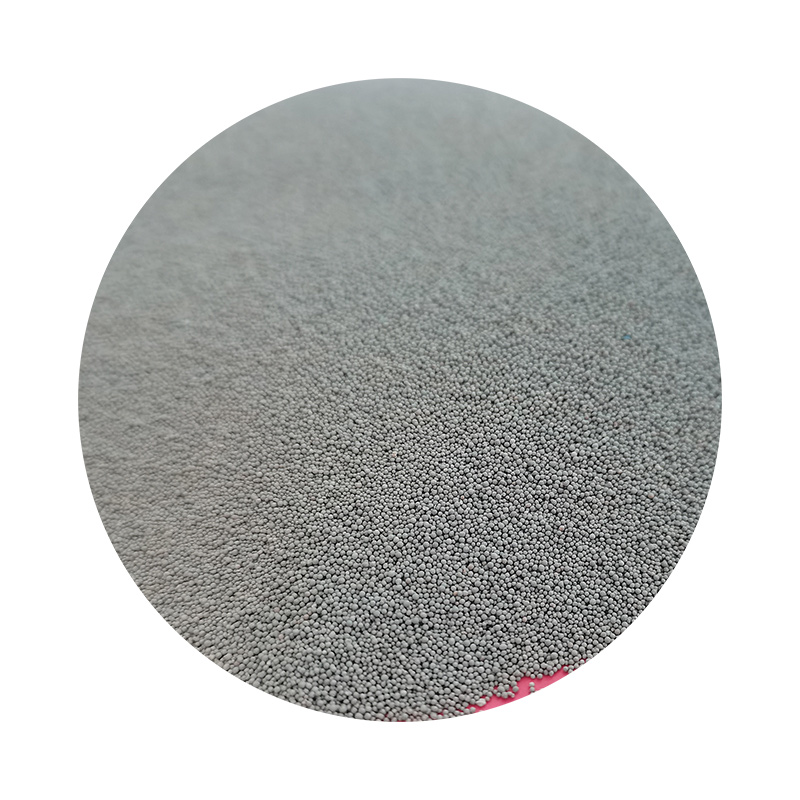

cerabeads sand

Environmental sustainability is another critical aspect of cerabeads sand. Traditional sand extraction can lead to significant ecological disruption, while cerabeads are manufactured from recycled materials, often including industrial by-products. This makes their production process more sustainable, contributing to a circular economy. Industries that adopt cerabeads are not only optimizing their operations but also reducing their environmental footprint, which is increasingly important in today’s world.

Another promising application of cerabeads sand is in the realm of surface treatments and coatings. Due to their smooth surface and spherical shape, cerabeads are an excellent choice for abrasive blasting processes. They provide a clean and efficient way to prepare surfaces for painting or coating applications. The use of cerabeads minimizes the generation of dust and harmful pollutants, contributing to a safer working environment.

In summary, cerabeads sand stands out as a multifunctional material with significant industrial advantages. From enhancing the quality of metal castings to improving construction materials and facilitating cleaner surface treatments, its applications are diverse and beneficial. As industries continue to seek sustainable and high-performance solutions, cerabeads sand is poised to play a vital role in the future of material science. With ongoing research and development, the potential for cerabeads to impact various sectors is vast, promising exciting advancements in technology and sustainability.

Post time:سېنتەبىر . 27, 2024 06:23

Next:Dichtheid van gietzand en de impact op gietprocessen