How to Sand Ceramic A Comprehensive Guide

Sanding ceramic can be a daunting task, but with the right techniques and tools, it can also be a rewarding process that enhances the look of your ceramics, removes imperfections, and prepares surfaces for glazing or painting. Whether you're working on a pottery piece, tiles, or ceramic surfaces, understanding how to sand it correctly is essential. In this article, we’ll explore the process of sanding ceramic, the tools you'll need, and some tips to achieve the best results.

Understanding the Basics of Ceramic

Ceramic is a durable material, made from clay and other raw materials, which are sintered at high temperatures. This process gives ceramics their hard and often glossy finish. However, this same hardness also means that sanding ceramic requires specific techniques and tools to effectively smooth rough surfaces or refine edges.

Tools You Will Need

1. Sanding Blocks These come in various shapes and sizes and are designed to hold sandpaper securely. Choose blocks that fit comfortably in your hand for better control.

2. Sandpaper Different grits of sandpaper serve various purposes - Coarse Grit (40-80) Useful for removing large imperfections or quickly shaping a piece. - Medium Grit (120-220) Ideal for smoothing down the surface after using coarse sandpaper. - Fine Grit (320-600 and above) Best for achieving a smooth finish and preparing the surface for glazing.

4. Safety Gear Always wear a dust mask and safety goggles to protect yourself from dust and particles while sanding.

Steps to Sand Ceramic

1. Prepare Your Work Area Ensure you are working in a well-ventilated area to minimize inhalation of dust particles. Lay down a protective cloth or newspaper to catch any debris.

how to sand ceramic

2. Identify the Areas to Sand Inspect your ceramic piece for any blemishes, rough spots, or areas that require smoothing. Mark these areas lightly with a pencil to guide your sanding.

3. Start with Coarse Grit Sandpaper Using a sanding block, begin with the coarse grit sandpaper. Apply gentle pressure and sand evenly in a back-and-forth motion. Avoid pressing too hard, as this can lead to uneven surfaces or scratches.

4. Progress to Medium Grit Once you have addressed the rough spots, switch to medium grit sandpaper. This will help smooth out the surface and prepare it for finer sanding.

5. Finish with Fine Grit Sandpaper For the final touch, use fine grit sandpaper. This will ensure that your ceramic piece is smooth and ready for glazing or painting. Take your time with this step, as the finer the finish, the better the final result will be.

6. Clean the Surface After sanding, clean the ceramic piece with a damp cloth to remove any dust and debris. Make sure it is completely dry before applying any finishes.

7. Inspect Your Work Take a close look at the piece to ensure you have achieved the desired smoothness. If necessary, repeat the sanding process in any areas that still feel rough.

Tips for Successful Sanding

- Test on a Small Area If you’re unsure about how the ceramic will respond to sanding, test on a small, inconspicuous area first. - Use a Light Touch Sanding ceramic can quickly lead to an uneven surface if too much pressure is applied. Always start with a light touch and gradually increase pressure as needed. - Take Breaks Don’t rush the sanding process. Frequent breaks will help you maintain focus and control, leading to better results. - Stay Consistent Keep your sanding motion consistent to avoid creating uneven spots on the surface.

Conclusion

Sanding ceramic may seem challenging, but with the right tools and techniques, it can be accomplished with ease and precision. Always take your time and be patient with the process. Whether you’re preparing a piece for a finish or simply refining its appearance, proper sanding techniques will enhance the beauty and durability of your ceramic work. Embrace the art of sanding, and enjoy creating beautiful ceramic pieces that reflect your skill and artistic vision.

Post time:Kas . 07, 2024 09:14

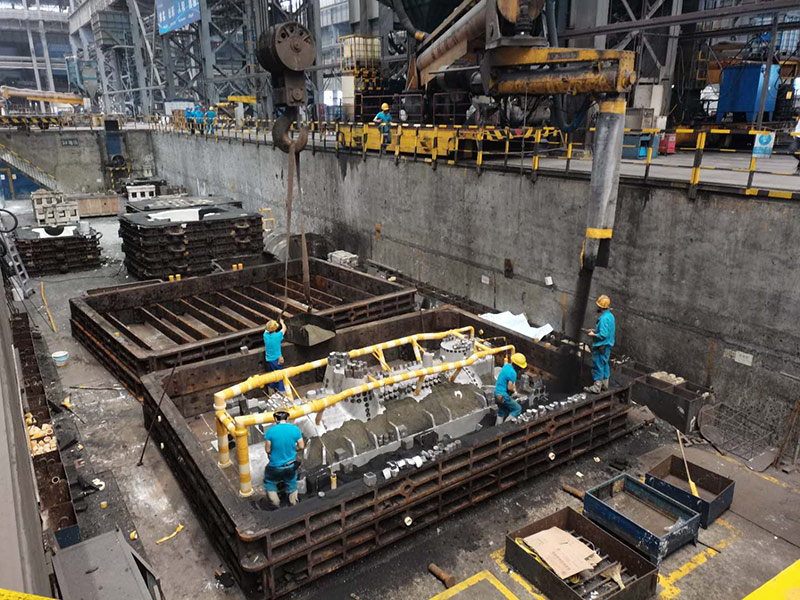

Next:A Step-by-Step Guide to Effective Sand Casting Techniques for Beginners