How to Sand a 3D Print A Comprehensive Guide

3D printing has revolutionized the way we create objects, from prototypes to intricate designs. However, the surface quality of 3D prints can sometimes leave much to be desired. Layer lines, rough spots, and other imperfections can detract from the overall look of a printed item. One effective solution to enhance the finish of your 3D prints is sanding. This guide will explore how to sand a 3D print effectively, ensuring a smooth and professional finish.

Understanding the Basics of 3D Prints

Before diving into sanding, it is important to understand the nature of 3D prints. Most 3D printing processes, such as Fused Deposition Modeling (FDM), create objects layer by layer. This process inevitably leaves visible layer lines, especially on vertical surfaces. Sanding helps to smooth these lines and create a more aesthetically pleasing finish.

Tools and Materials Needed

To achieve the best results when sanding a 3D print, you'll need several tools and materials

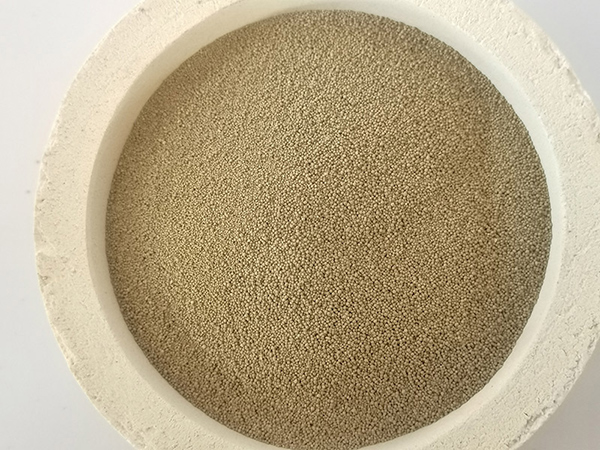

1. Sandpaper Use a variety of grits, typically starting from coarse (100-200 grit) to fine (800-1000 grit). Coarse paper helps to remove large imperfections, while fine paper smooths the surface. 2. Sanding Sponge These are great for getting into difficult shapes and curves, ensuring that you don’t miss any spots.

3. Water or Isopropyl Alcohol Wet sanding can minimize dust and provide a smoother finish. Using water or alcohol can also help to soften the plastic slightly, making it easier to sand.

4. Dust Mask and Safety Goggles Protect yourself from dust particles generated during the sanding process.

5. Vacuum or Brush To clean off debris as you work.

Step-by-Step Sanding Process

how to sand a 3d print

1. Preparation Start by cleaning your print from any remaining support material. Use a pair of pliers or a knife to carefully remove supports without damaging the print. Once this is done, ensure the print is free from dust or grease.

2. Start with Coarse Grit Begin sanding with coarse grit sandpaper (around 100-200 grit). Sand the surface in a circular motion or along the direction of the grain to remove the most significant layer lines. Be careful not to apply too much pressure, as this may gouge the material.

3. Switch to Medium Grit Once the majority of the rough spots and layer lines are removed, transition to medium grit sandpaper (around 300-400 grit). This step will help to smooth out any scratches left by the coarse sandpaper.

4. Wet Sanding For a finer finish, consider wet sanding with medium grit sandpaper. Dip the sandpaper in water or apply isopropyl alcohol. This process prevents dust and helps achieve a smoother surface by reducing friction.

5. Finishing Touch After you have achieved a smoother surface with medium grit, move on to fine grit sandpaper (800-1000 grit). This step will help you achieve a polished look. Remember to keep the surface wet if you are wet sanding.

6. Clean Up After sanding, thoroughly clean the print to remove any remaining dust or particles. A vacuum or a soft brush can be effective at this stage.

7. Optional - Coating For an even more polished appearance, consider applying a coating such as a primer or paint. This can help further hide minor imperfections and add a layer of protection to your print.

Tips for Success

- Test on a Scrap Piece If you are new to sanding 3D prints, practice on a scrap piece first to get a feel for the process. - Patience is Key Sanding can be time-consuming, especially for larger prints. Take your time to achieve the best results. - Observe and Adjust Continuously check your progress. If the surface looks smooth enough after one grit, move on to the next.

Conclusion

Sanding a 3D print can significantly enhance its appearance, transforming a rough print into a sleek, professional-looking object. By following these steps and experimenting with different techniques, you can master the art of sanding and elevate your 3D printing projects. Whether for personal use or professional displays, a well-sanded print can make all the difference. Happy sanding!

Post time:Ara . 18, 2024 19:23

Next:sand casting iron