The Rise of China’s Sand Casting Factory Industry

In recent years, China has established itself as a global leader in manufacturing and industrial production. One of the key areas that have flourished in this environment is the sand casting industry. Sand casting, a traditional method of metal casting, involves pouring molten metal into a mold made from sand. This versatile process is widely used in producing complex metal parts and components for various industries, including automotive, aerospace, and heavy machinery.

China's sand casting factories are at the forefront of this manufacturing method, combining traditional techniques with modern technology to enhance efficiency and product quality. The country boasts an extensive network of foundries that cater to both domestic and international demands. The scale and capabilities of these factories enable them to produce a vast array of components, from small intricate parts to large heavy-duty castings.

The Rise of China’s Sand Casting Factory Industry

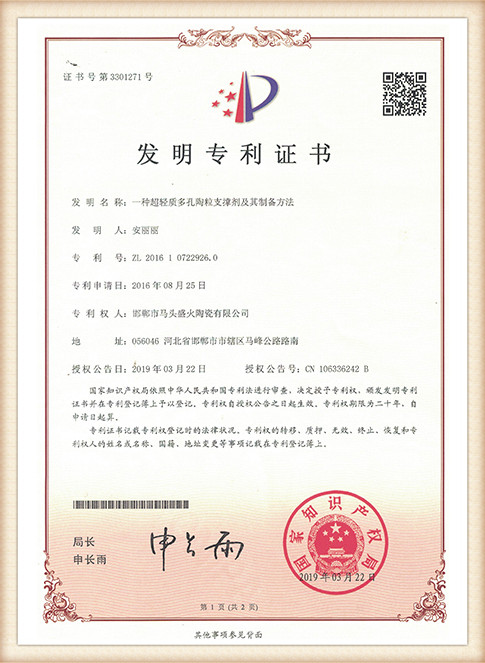

Quality control is paramount in the sand casting process, and Chinese factories are investing in advanced technologies to ensure that their products meet international standards. Many foundries have implemented rigorous quality assurance protocols, utilizing state-of-the-art testing and inspection equipment. This focus on quality has enabled them to achieve certifications such as ISO 9001, which reassures clients that they are receiving reliable and durable products.

china sand casting factory

In addition to quality and cost, flexibility is another factor that makes Chinese sand casting factories attractive to businesses worldwide. Many factories are equipped to handle small to medium-sized production runs, allowing clients to produce custom components without the need for large upfront investments. This flexibility is particularly appealing to industries that require rapid prototyping and short lead times, such as the automotive sector.

The commitment to innovation in China’s sand casting industry is also noteworthy. Many factories are incorporating advanced technologies such as 3D printing and computer-aided design (CAD) into their processes. These technologies facilitate the rapid creation of molds and prototypes, significantly reducing production time and costs. As a result, factories can respond quickly to market demands and customer specifications, maintaining a competitive edge in a fast-paced global market.

Environmental considerations are becoming increasingly important in manufacturing, and China’s sand casting factories are making strides in this area. Many foundries are adopting environmentally friendly practices, such as recycling sand and using eco-friendly binders in the casting process. This shift not only helps in reducing waste but also aligns with global sustainability efforts, appealing to eco-conscious clients.

In conclusion, the sand casting factory industry in China is poised for continued growth and innovation. With its combination of cost-effective production, stringent quality control, flexibility, and technological advancement, China is solidifying its position as a key player in the global sand casting market. As industries around the world seek reliable, high-quality, and affordable casting solutions, China's sand casting factories are likely to remain a preferred choice for many years to come. The future of sand casting in China not only promises enhanced manufacturing capabilities but also a commitment to sustainability and environmental responsibility.

Post time:Ara . 10, 2024 14:31

Next:Advancements in Ceramic Sand Casting Techniques for Enhanced Molding and Casting Quality