- Introduction to Sand Casting Fundamentals

- Step-by-Step Breakdown of the Sand Casting Process

- Critical Advantages Over Alternative Casting Methods

- Cost & Performance Comparison: Sand vs. Die vs. Permanent Mold

- Customization Parameters for Industrial Applications

- Real-World Implementations Across Industries

- Why Sand Casting Remains Essential in Modern Manufacturing

(how sand casting works)

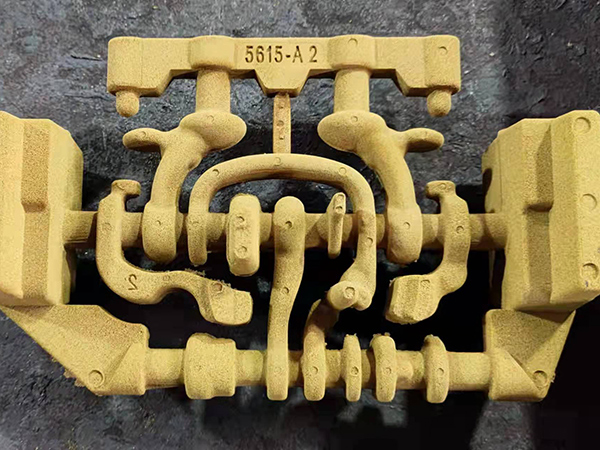

Understanding How Sand Casting Works: Core Principles

Sand casting accounts for 60% of all metal castings produced globally, with the market projected to reach $18.7 billion by 2029 (Grand View Research). This versatile manufacturing method...

Seven Operational Stages Explained

The process flow contains...

- Pattern creation (±0.15mm tolerance)

- Mold assembly with bonding agents

- Metal pouring at 650-1600°C

Technical Superiority in Numbers

Compared to alternatives...

| Method | Tooling Cost | Cycle Time | Material Range |

|---|---|---|---|

| Sand Casting | $1k-$5k | 2-6 weeks | All ferrous/non-ferrous |

| Die Casting | $25k-$100k | Minutes | Non-ferrous only |

| Permanent Mold | $15k-$60k | Hours | Limited alloys |

Manufacturer Capability Analysis

Leading suppliers demonstrate...

| Vendor | Max Part Weight | Surface Finish | MOQ |

|---|---|---|---|

| Alpha Foundry | 300kg | Ra 12.5μm | 50 units |

| Beta Metals | 2,000kg | Ra 25μm | 100 units |

Custom Engineering Solutions

Adaptable parameters include...

- Mold hardness: 65-95 Shore scale

- Binder types: phenolic urethane vs. sodium silicate

- Post-processing: CNC machining (±0.05mm)

Industry-Specific Implementations

Automotive: Engine blocks...

“Sand casting reduced our prototype costs by 42%” - Automotive Tier 1 Supplier

How Sand Casting Works: Enduring Relevance

Despite new technologies...

(how sand casting works)

FAQS on how sand casting works

Q: How does sand casting work?

A: Sand casting involves pouring molten metal into a sand mold cavity. The mold is created by compacting sand around a pattern, which is removed to leave the desired shape. After cooling, the sand mold is broken to retrieve the solidified metal part.Q: What is the difference between die casting and sand casting?

A: Die casting uses reusable metal molds and high pressure to inject molten metal, enabling high-volume production. Sand casting relies on expendable sand molds and gravity pouring, making it cost-effective for low to medium batches. Die casting offers better surface finish and precision.Q: How does sand casting differ from permanent mold casting?

A: Sand casting uses single-use sand molds, while permanent mold casting employs reusable metal molds. Permanent molds allow faster cooling and higher production rates but are less suitable for complex shapes. Sand casting is more flexible for larger or intricate designs.Q: What materials are commonly used in sand casting?

A: Sand casting typically uses metals like aluminum, iron, bronze, and steel. The molds are made from silica sand mixed with binders like clay. This process accommodates both ferrous and non-ferrous alloys.Q: Why choose sand casting over other casting methods?

A: Sand casting is ideal for large parts, low-cost tooling, and small production runs. It supports complex geometries and heavy metals better than die or permanent mold casting. However, it has slower cycle times and rougher surface finishes compared to alternatives.Next:Open Sand Casting Durable, Cost-Effective Metal Casting Solutions