The Art and Science of 3D Printing Sanding Enhancing the Finish

3D printing has revolutionized the manufacturing landscape, opening new avenues for creativity and production. As the technology continues to evolve, one area that merits particular attention is post-processing, specifically sanding. Sanding is a crucial step in refining the surface finish of 3D printed objects, ensuring that they meet aesthetic and functional requirements. This article delves into the significance of sanding in 3D printing, the techniques involved, and best practices to achieve optimal results.

The Importance of Sanding in 3D Printing

The primary draw of 3D printing lies in its ability to create complex geometries that would be impossible or cost-prohibitive with traditional manufacturing methods. However, the layer-by-layer nature of 3D printing often results in visible layer lines, rough textures, and imperfections on the surface of the finished product. Sanding serves as an essential post-processing technique to mitigate these issues, allowing creators to achieve a smoother, more polished finish.

Moreover, sanding enhances the overall quality and durability of the printed object. A smooth surface can improve adhesion when applying paint or other finishes, ensuring a more uniform coat. For functional parts, such as mechanical components or prototypes, a polished surface can reduce friction and improve performance.

Techniques and Tools for Sanding

When it comes to sanding 3D printed objects, various techniques and tools can be employed, depending on the material used and the desired finish. Here are some common methods

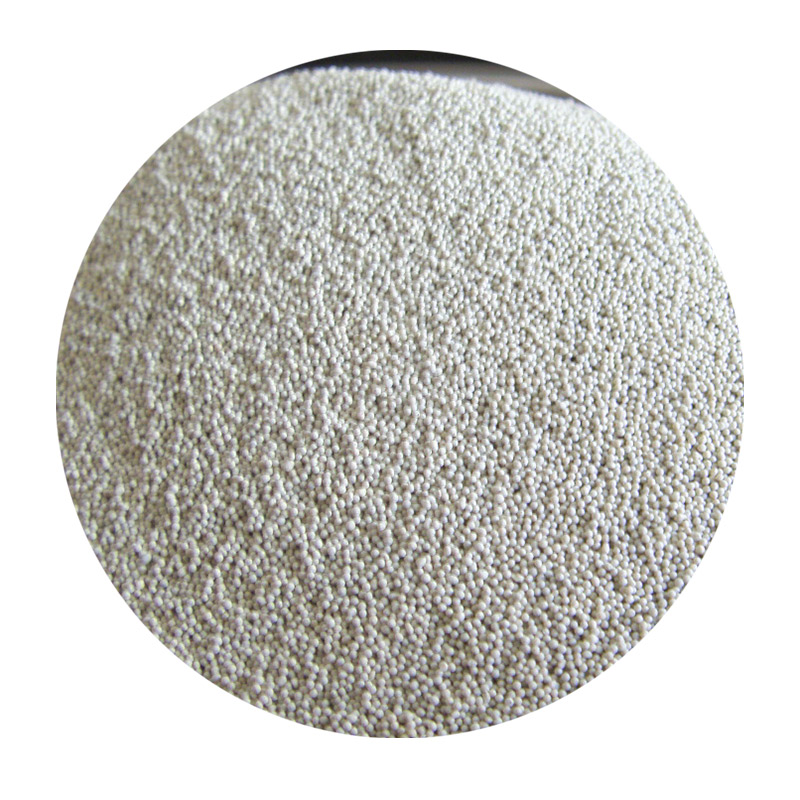

1. Manual Sanding The traditional method involves using sandpaper to manually sand the surface of the print. Sandpaper is available in various grits, from coarse (lower numbers) to fine (higher numbers). A typical approach starts with a coarser grit to remove significant imperfections, followed by progressively finer grits to achieve a smooth finish.

2. Power Tools For larger objects or intricate designs, power tools such as rotary sanders or oscillating tools can expedite the sanding process. These tools can cover more area quickly, but care must be taken to avoid damaging the print, particularly on delicate features.

3. Sanding Blocks Using a sanding block can provide even pressure and a flat surface when sanding larger areas. It can be particularly helpful in maintaining control and minimizing the risk of rounding edges inadvertently.

3d printing sanding

4. Wet Sanding This technique involves dampening the sandpaper before use, which can help reduce dust and improve results. Wet sanding can be especially effective for materials like PLA and ABS, providing a fine finish and preventing clogging of the sandpaper.

5. Chemical Smoothing While not traditional sanding, chemical smoothing is an alternative method for finishing prints, especially those made from materials like ABS. Acetone vapor can be used to dissolve the surface layer slightly, resulting in a shiny, smooth finish. However, this process requires careful handling of chemicals for safety.

Best Practices for Effective Sanding

To achieve the best results when sanding 3D printed objects, consider the following best practices

- Start with Coarse Grit Begin with a lower grit sandpaper to remove noticeable layer lines and imperfections. Transition to finer grits progressively for a smoother finish.

- Use Consistent Pressure Apply even pressure during sanding to prevent uneven surfaces. Avoid excessive pressure that can lead to warping or damaging features.

- Clean Between Sessions Regularly clean the surface from dust and debris accumulated during sanding. This helps maintain effectiveness and prevents scratches from leftover particles.

- Finish with a Polish After achieving a smooth surface, applying a polishing compound can provide an extra layer of shine, enhancing the aesthetic appeal of the printed object.

In conclusion, sanding is an integral part of the 3D printing process, transforming raw prints into professionally finished products. By employing effective techniques and following best practices, creators can significantly enhance the quality, aesthetics, and functionality of their 3D printed designs. As the field of 3D printing advances, the art and science of sanding will continue to play a vital role in realizing the full potential of this groundbreaking technology.

Post time:Nov . 06, 2024 04:14

Next:Exploring the Unique Aesthetic of Heath Ceramics Sand Color Collection