How Accurate is Sand Casting?

Sand casting, one of the oldest methods of metal casting, has been a staple in manufacturing for centuries. Its versatility, cost-effectiveness, and relative simplicity make it a popular choice for producing complex metal shapes. But how accurate is sand casting compared to other methods? This article delves into the accuracy of sand casting and the factors that influence it.

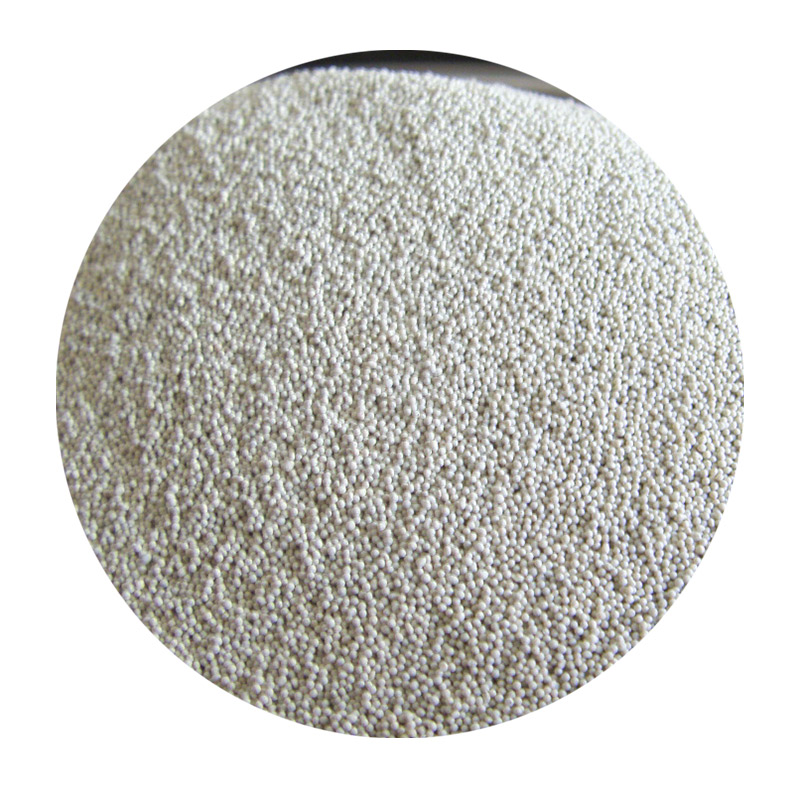

The Basics of Sand Casting

The sand casting process involves creating a mold from a mixture of sand and a binding agent. Once the mold is prepared, molten metal is poured into it, cooled, and then removed to reveal the final cast product. While sand casting is well-suited for large and intricate shapes, the accuracy of the finished piece can vary.

Factors Influencing Accuracy

1. Mold Design The precision of the mold significantly impacts the final dimensions of the cast part. Well-designed molds can enhance accuracy by reducing defects and ensuring a better fit.

2. Material Quality The quality of the sand and binding agent used plays a critical role in achieving accuracy. High-quality materials can reduce the likelihood of sand sticking to the metal and minimize shrinkage during cooling.

3. Pattern Tolerances Patterns, which are replicas of the intended final product, can affect overall accuracy. If a pattern is not made to exact specifications or is subject to wear, it can lead to discrepancies in the final casting.

4. Casting Process Parameters Variables such as temperature control, pouring techniques, and cooling rates can alter the shape and dimensions of the cast product, affecting accuracy.

how accurate is sand casting

5. Post-Casting Treatments After casting, processes such as machining and finishing can be employed to correct any dimensional discrepancies, thereby improving overall accuracy.

Accuracy Range

In terms of accuracy, sand casting typically achieves tolerances ranging from ±0.5 mm to ±2.5 mm for castings up to 1 meter in size. This level of precision is generally acceptable for many applications and industries, although it may fall short of the tolerances achieved by other methods like investment casting or die casting, which can reach tolerances as tight as ±0.1 mm.

Advantages and Limitations

Despite its limitations in precision, sand casting offers several advantages that can make it the preferred choice for various applications. The process can accommodate large parts and complex geometries that might be challenging or expensive to produce using other methods. Additionally, the ability to cast a wide range of metals, from aluminum to iron, adds to its versatility.

However, for applications where high precision is paramount, manufacturers might opt for alternatives like investment casting, which, while more expensive, can provide better accuracy and surface finish.

Conclusion

In conclusion, sand casting is a reliable method for producing metal parts with decent accuracy for many applications. While its tolerances may not match those of more advanced casting methods, its affordability, scalability, and versatility make it an enduring choice in the manufacturing sector. Understanding the factors that influence accuracy can help manufacturers optimize the sand casting process and achieve better results tailored to their specific needs.

Post time:ต.ค. . 08, 2024 07:16

Next:gold sand for sale