The Importance of Sand Casting in Modern Manufacturing

Sand casting, one of the oldest and most versatile manufacturing processes, continues to play a significant role in modern industry. This process involves creating a mold from a sand mixture, which is then used to cast metal into various shapes and forms. Sand casting is particularly valued for its flexibility, cost-effectiveness, and ability to produce complex geometries. In this article, we will explore the significance of sand casting companies in contemporary manufacturing.

The Importance of Sand Casting in Modern Manufacturing

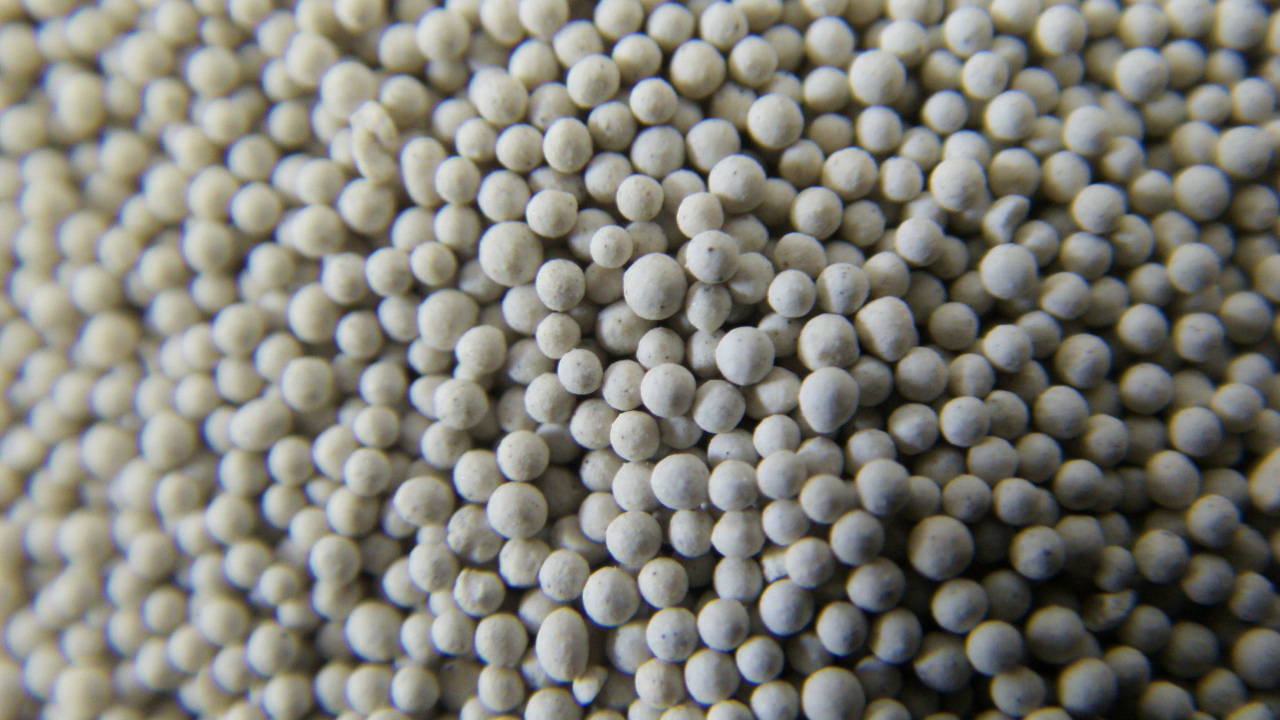

Cost-effectiveness is another critical factor that enhances the appeal of sand casting. The materials used in sand casting, primarily sand and metal, are relatively inexpensive. Additionally, the process allows for the reuse of sand, which further reduces waste and minimizes costs. For small businesses and startups, this affordability means that high-quality metal parts can be produced without prohibitive initial investments. Sand casting companies thus serve as a bridge for innovation, enabling firms to prototype and produce parts with lower financial risks.

sand casting company

Moreover, sand casting is noted for its ability to produce complex shapes that would be challenging or even impossible to achieve through other manufacturing methods. The process can incorporate intricate designs, thin walls, and undercuts, which are often required in modern engineering. This capability opens up a world of possibilities for design engineers who wish to innovate without being constrained by manufacturing limitations.

In addition to these practical benefits, sand casting companies contribute significantly to the local economies. They provide employment opportunities for skilled labor in various roles, including mold makers, machine operators, and quality control inspectors. This local expertise fosters community development and strengthens the economy, making sand casting not only a manufacturing process but also a cornerstone of local industry.

Environmentally, sand casting has made strides towards sustainability. The industry has increasingly focused on minimizing its environmental impact by improving recycling processes for sand and reducing the energy consumption associated with metal casting. Additionally, advancements in technology have led to the development of more eco-friendly binder materials, which are used alongside sand in the mold-making process. These innovations contribute to a more sustainable approach to manufacturing, aligning with the global shift toward environmentally responsible practices.

In conclusion, sand casting companies are essential players in the modern manufacturing landscape. Their ability to produce a wide range of metal parts cost-effectively, their adaptability to complex designs, and their role in local economies underscore their importance. As industries continue to evolve, sand casting will remain a vital manufacturing technique, bridging the gap between traditional practices and modern demands. With ongoing innovations and a focus on sustainability, the future of sand casting looks promising, ensuring its continued relevance in the industrial world.

Post time:సెప్టెం . 10, 2024 06:38

Next:fill 3d print with sand