- Overview of Lost Foam Sand Casting Technology

- Technical Advantages Driving Industry Adoption

- Leading Manufacturers: Capabilities Comparison

- Custom Solutions for Diverse Industrial Needs

- Material Selection and Process Optimization

- Quality Control in Foam Casting Production

- Future Outlook for Precision Casting Methods

(lost foam sand casting)

Understanding Lost Foam Sand Casting: A Game-Changer in Metal Fabrication

Lost foam sand casting (LFSC) has revolutionized metal component production since its commercialization in the 1980s, now accounting for 18% of global casting output according to the World Foundry Organization. This evaporative-pattern process enables complex geometries unachievable through traditional methods, with dimensional accuracy improvements of 40-60% compared to green sand casting.

Technical Superiority in Modern Manufacturing

Three core advantages position LFSC as the preferred method for precision components:

- Design Freedom: 95% reduction in machining requirements through near-net shaping

- Surface Finish: 125-250 µin roughness vs. 500-1000 µin in conventional casting

- Material Efficiency: 30-45% less metal waste through optimized foam patterns

Manufacturer Capabilities Analysis

| Manufacturer | Annual Capacity | Max Part Weight | Tolerance Range |

|---|---|---|---|

| AlphaCast Solutions | 25,000 tons | 150 kg | ±0.3mm |

| PrecisionFoam Tech | 18,000 tons | 85 kg | ±0.15mm |

| GlobalFoundry Group | 42,000 tons | 300 kg | ±0.5mm |

Tailored Casting Solutions

Modern lost foam casting materials enable customized approaches:

- Automotive: 1,200+ cylinder heads/week production for diesel engines

- Aerospace: Titanium components with 0.12mm wall thickness

- Construction: 8-ton capacity pump housings with integrated cooling channels

Advanced Material Applications

The global lost foam casting materials market reached $2.7 billion in 2023, driven by:

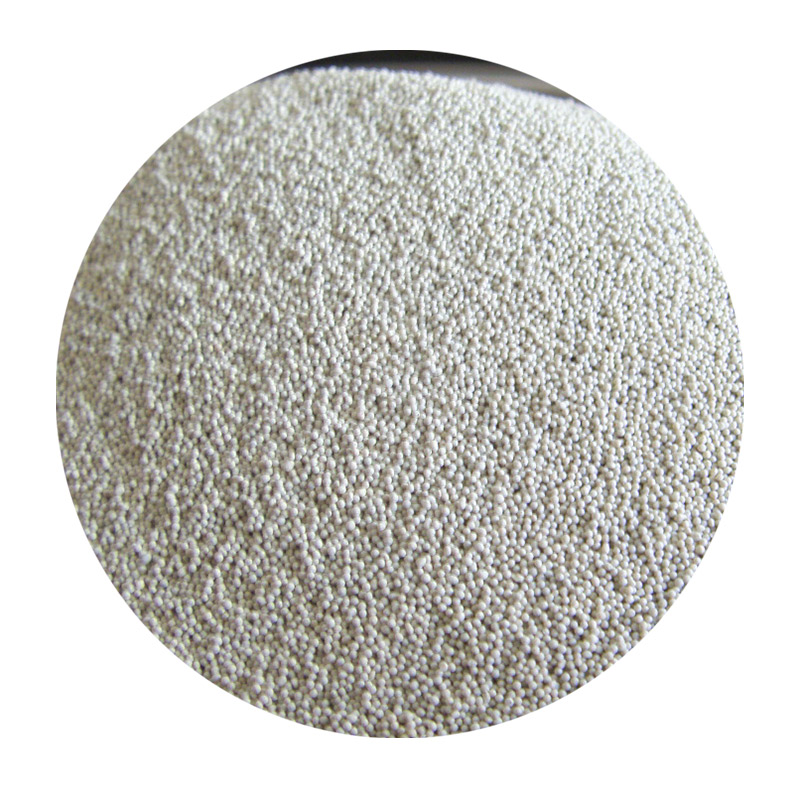

- High-density EPS foams (24-32 kg/m³)

- Polymer-coated sand systems

- Low-carbon steel alloys (SAE 1010-1020)

Production Quality Assurance

Top manufacturers implement multi-stage verification:

- X-ray defect detection (99.2% accuracy)

- Real-time thermal monitoring (±5°C control)

- 3D scanning validation (0.05mm resolution)

Lost Foam Casting: Shaping Manufacturing's Future

With 7.8% CAGR projected through 2030, LFSC continues displacing traditional methods. Recent advancements in 3D-printed foam patterns and biodegradable materials address both precision and environmental concerns, solidifying its position in sustainable manufacturing.

(lost foam sand casting)

FAQS on lost foam sand casting

Q: What is lost foam sand casting?

A: Lost foam sand casting is a metal casting process where a foam pattern is embedded in sand, then molten metal replaces the vaporized foam, creating precise and complex shapes with minimal finishing.

Q: What materials are used in lost foam casting?

A: Key materials include expandable polystyrene (EPS) foam for patterns, refractory coatings, and unbonded silica sand. Binders and alloys like aluminum, iron, or steel are also critical components.

Q: How to choose reliable lost foam casting manufacturers?

A: Prioritize manufacturers with ISO certification, proven expertise in complex geometries, and material-specific experience. Review client testimonials and quality control processes for assurance.

Q: What are the advantages of lost foam sand casting?

A: It enables near-net-shape production, reduces machining needs, and accommodates intricate designs. The process also minimizes waste and supports diverse metal alloys.

Q: Why is foam material selection crucial in lost foam casting?

A: Foam density and composition directly affect pattern stability, gas emissions during pouring, and final surface finish. Proper selection prevents defects like slag inclusions or dimensional inaccuracies.

Next:History of Sand Casting Evolution, Techniques & Modern Uses