The Difference Between Sand Casting and Investment Casting

Casting is a fundamental manufacturing process used to shape metals and alloys into desired forms. Among the various casting techniques, sand casting and investment casting are two widely used methods, each with its own set of characteristics, advantages, and applications. Understanding the differences between these two casting techniques can help manufacturers choose the right process for their specific needs.

Sand Casting

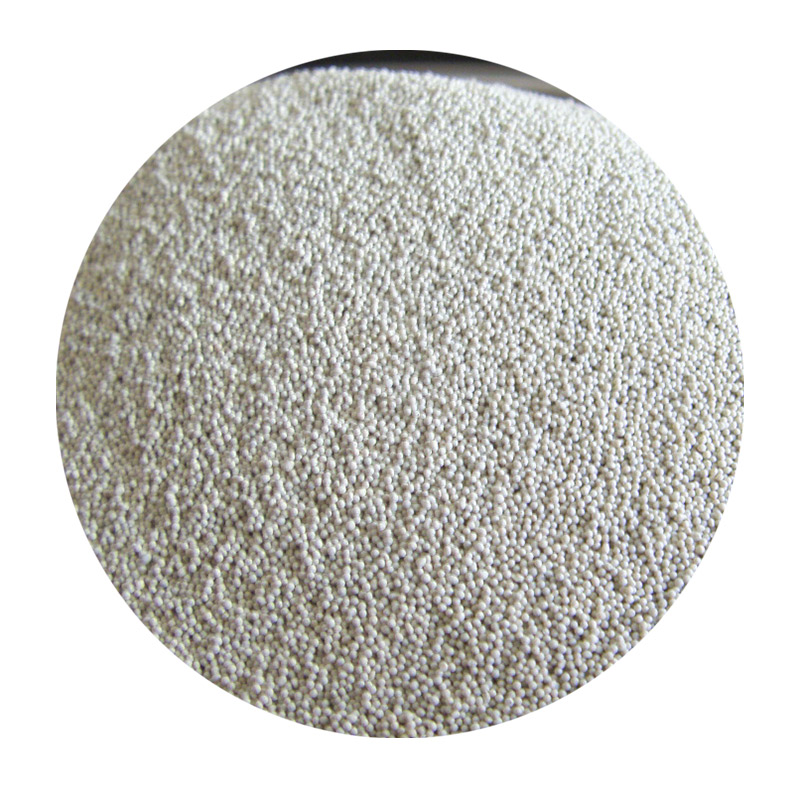

Sand casting, one of the oldest casting methods, involves creating a mold from a mixture of sand, clay, and water. The process begins with forming two halves of a mold by packing the sand mixture around a pattern that represents the desired shape of the part. Once the mold is created, the pattern is removed, leaving behind a cavity into which molten metal is poured.

One of the primary advantages of sand casting is its versatility. It can accommodate a wide range of materials, including ferrous and non-ferrous alloys. Additionally, the process is suitable for producing large parts and intricate designs, as the sand mold can be easily shaped and modified. However, sand casting is generally less precise than other casting methods, such as investment casting. Surface finish and tolerances may require additional machining, especially for high-precision components.

Investment Casting

Investment casting, also known as lost-wax casting, utilizes a different approach. This method involves creating a wax pattern of the part, which is then coated with a ceramic material to form a mold. Once the ceramic shell is formed and hardened, the wax is melted away, leaving a precise cavity for the molten metal. After pouring the metal into the mold, the ceramic shell is broken away to reveal the finished part.

Investment casting is renowned for its ability to produce complex geometries with excellent surface finishes and tight tolerances. This makes it especially valuable for industries that require high precision, such as aerospace and medical device manufacturing. The process can accommodate a wide variety of metals and alloys, and it is particularly effective for small to medium-sized parts.

Key Differences

difference between sand casting and investment casting

The main differences between sand casting and investment casting can be summarized in several key areas

1. Mold Material Sand casting uses a mixture of sand and clay, while investment casting employs a ceramic shell, typically developed from a wax pattern.

2. Precision and Surface Finish Investment casting provides superior precision and surface quality compared to sand casting. This often eliminates the need for extensive machining post-casting, which might be necessary with sand cast parts.

3. Complexity of Design Investment casting excels in producing highly complex shapes that may be difficult or impossible to achieve with sand casting.

4. Production Volume Sand casting is more economical for larger production volumes and larger components, while investment casting is better suited for lower volumes of high-precision parts.

5. Lead Time and Cost Investment casting typically involves higher initial costs due to the wax pattern and ceramic shell process. However, it can lead to cost savings in finishing and machining for high-end applications.

Conclusion

In conclusion, sand casting and investment casting serve distinct purposes in the manufacturing world, each with its own advantages and limitations. Selecting the appropriate casting method depends on various factors, including the complexity of the part, the required precision, and the production volume. By understanding the differences between these two techniques, manufacturers can make informed decisions that align with their production goals and quality standards.

Post time:ஜன . 01, 2025 15:37

Next:Fusione della sabbia tecniche e trucchi per un progetto di successo