Understanding Custom Sand Casting A Comprehensive Overview

Custom sand casting is a versatile and economical manufacturing process that plays a crucial role in producing intricate metal components. This method is widely used across various industries, including automotive, aerospace, and machinery, thanks to its adaptability and efficiency.

What is Sand Casting?

Sand casting, also known as sand mold casting, is one of the oldest and most common methods of metal casting. The process involves creating a mold from a mixture of sand, clay, and water, which holds the shape of the desired component. This mold is then filled with molten metal, allowing it to cool and solidify before the mold is removed and the final product is retrieved.

Custom Sand Casting Process

The custom sand casting process consists of several critical steps

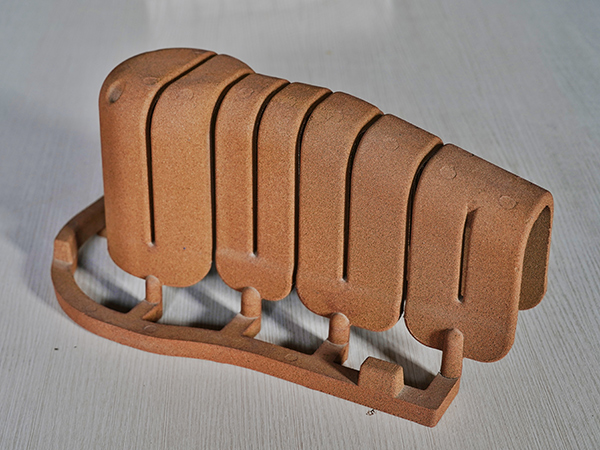

1. Designing the Pattern The first step in custom sand casting involves creating a pattern, which is a replica of the final product. Patterns can be made from various materials, including wood, plastic, or metal. Custom patterns are specifically designed to meet the unique specifications of the project, ensuring that the final casting accurately reflects the intended design.

2. Mold Preparation Once the pattern is made, it is used to create the sand mold. The mold is formed by packing sand around the pattern, which is then removed to leave a cavity in the shape of the part. The quality of the sand and the mold preparation directly impacts the finish and accuracy of the final cast.

3. Pouring the Molten Metal After the mold is prepared, molten metal is poured into the cavity. The selection of the metal used depends on the application and desired properties of the final product. Common metals used in sand casting include aluminum, iron, and bronze.

4. Cooling and Solidification The molten metal cools and solidifies within the mold. This phase is critical as the cooling rate can affect the material properties and surface finish. Once cooled, the mold is broken apart, and the cast part is removed.

5. Finishing Processes The final step in custom sand casting involves finishing processes, such as grinding, machining, or polishing, to achieve the desired surface finish and dimensional accuracy.

Advantages of Custom Sand Casting

custom sand casting

Custom sand casting offers numerous advantages, including

- Versatility This method can accommodate a wide range of shapes and sizes, making it suitable for producing complex geometries that may be challenging for other manufacturing methods.

- Cost-Effectiveness Sand casting is relatively inexpensive compared to other casting techniques, especially when it comes to low-volume production

.- Material Selection A variety of metals can be used, allowing designers to choose the material that best suits the application’s requirements.

- Scalability Custom sand casting can efficiently handle both small batches and large production runs, offering flexibility in manufacturing.

Industries Benefiting from Custom Sand Casting

Numerous industries leverage custom sand casting for their specific needs. For instance

- Automotive Industry Custom sand casting is often used to produce engine blocks, transmission cases, and other structural components.

- Aerospace Sector Critical parts like turbine housings and brackets are manufactured using precision sand casting methods.

- Industrial Machinery Components such as gears, valves, and housings are produced to meet strict operational standards and performance.

Conclusion

Custom sand casting continues to be a preferred manufacturing method due to its adaptability, cost-effectiveness, and ability to create complex geometries. As industries evolve and demand for precision and efficiency grows, the significance of custom sand casting is likely to increase, solidifying its place in modern manufacturing solutions. Whether it’s producing small prototypes or large-scale components, this versatile casting method remains a cornerstone of many industrial applications.

Post time:அக் . 20, 2024 13:53

Next:3d printing for sand casting