Sintering Sand The Key to Advanced Material Engineering

Sintering is a vital process in the field of material engineering, particularly when it comes to the production of ceramics and metal parts. Within this context, sintering sand plays a crucial role. It refers to fine sand particles that are used in a wide array of applications, including metal casting, 3D printing, and the manufacturing of ceramic materials. The process of sintering utilizes heat to fuse particles together without causing them to melt completely, which is essential for creating durable and high-quality materials.

One of the primary applications of sintering sand is in the production of sand molds for metal casting. In this process, the sand is mixed with binders and shaped into molds that can withstand high temperatures during casting. This method offers several advantages it is cost-effective, produces complex shapes, and allows for rapid prototyping of metal parts. Moreover, sintered sand molds can provide excellent surface finishes, which reduces the need for additional machining after casting.

Sintering sand is also gaining prominence in the realm of additive manufacturing. In 3D printing, a specific type of sand—known as silica sand—is used in binder jetting and other processes. By carefully controlling the sintering temperatures, manufacturers can create intricate parts that would be challenging to achieve through traditional methods. The ability to produce lightweight structures with high strength makes sintered sand an attractive alternative for industries such as aerospace and automotive.

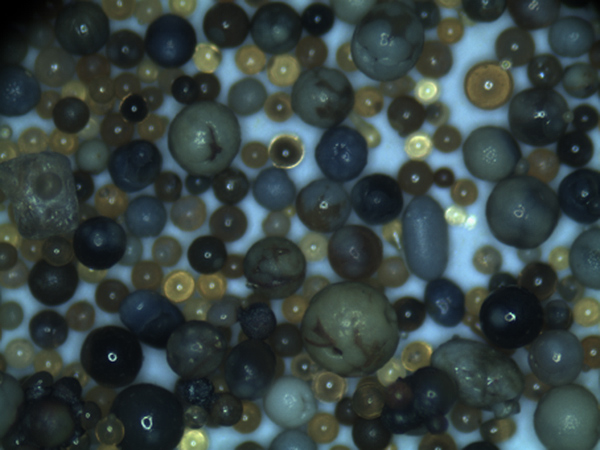

sintering sand

The material properties of sintering sand are critical to the success of these applications. The grain size, shape, and distribution of sand particles can significantly influence the final product's mechanical properties. For instance, finer grains tend to result in a denser pack and improved strength, while coarser grains may lead to superior drainage and air flow during processes like metal casting. Engineers and material scientists continuously study these properties to optimize the sintering process for specific applications.

Furthermore, sustainability is becoming an increasingly important factor in the use of sintering sand. With growing environmental concerns, researchers are actively seeking ways to reduce waste and enhance the recyclability of materials used in sintering. One promising approach is to develop green binders made from renewable resources, which can replace traditional synthetic binders. This shift not only reduces the carbon footprint of the sintering process but also enhances the overall circularity of sand materials.

In conclusion, sintering sand is more than just a simple raw material; it is a foundational element in various cutting-edge manufacturing processes. From metal casting to additive manufacturing, the role of sintering sand is essential in producing high-quality materials that meet the demands of modern industries. As technologies and environmental standards evolve, the advancements in sintering sand processes will likely continue, leading to smarter and more sustainable manufacturing practices. Embracing these innovations will be key for sectors that rely on precision engineering and high-performance materials. As we move forward, the synergy between sintering sand and advanced material engineering will undoubtedly shape the future of manufacturing.

Post time:Septemba . 02, 2024 21:55

Next:ceramsite