The Process of Sand Sintering An In-Depth Analysis

Sintering is a pivotal process in materials science, particularly when it comes to creating solid materials from powders. Among the various forms of sintering, sand sintering has emerged as a significant technique, particularly in the construction and manufacturing industries. This article will explore the intricacies of sand sintering, its applications, and its benefits.

What is Sand Sintering?

Sand sintering involves the process of merging fine sand particles together through heat application without reaching the melting point of the material. Typically, this process is employed to create durable and robust structures or components. The sand particles are often combined with binders or additives that assist in the sintering process and improve the final product's properties.

The Sintering Process

The sand sintering process can be broken down into several key stages

1. Preparation of Sand The first step involves selecting the appropriate type of sand, which can vary based on the desired properties of the final product. Silica sand is commonly used due to its abundance and favorable properties.

2. Mixing The selected sand is mixed with binders and additives. These can include clay, cement, or chemical agents that promote adhesion between sand particles when heated.

3. Molding The mixture is then placed into molds to shape the final product. This can include anything from bricks and tiles to intricate designs used in architecture and art.

4. Heating The molded sand is carefully heated in a furnace. The temperature is controlled to ensure that the sand particles adhere to one another without melting. This stage is critical as it determines the strength and durability of the final product.

5. Cooling Once the sintering is complete, the material is gradually cooled. This step is crucial as rapid cooling can lead to cracks or other defects in the final product.

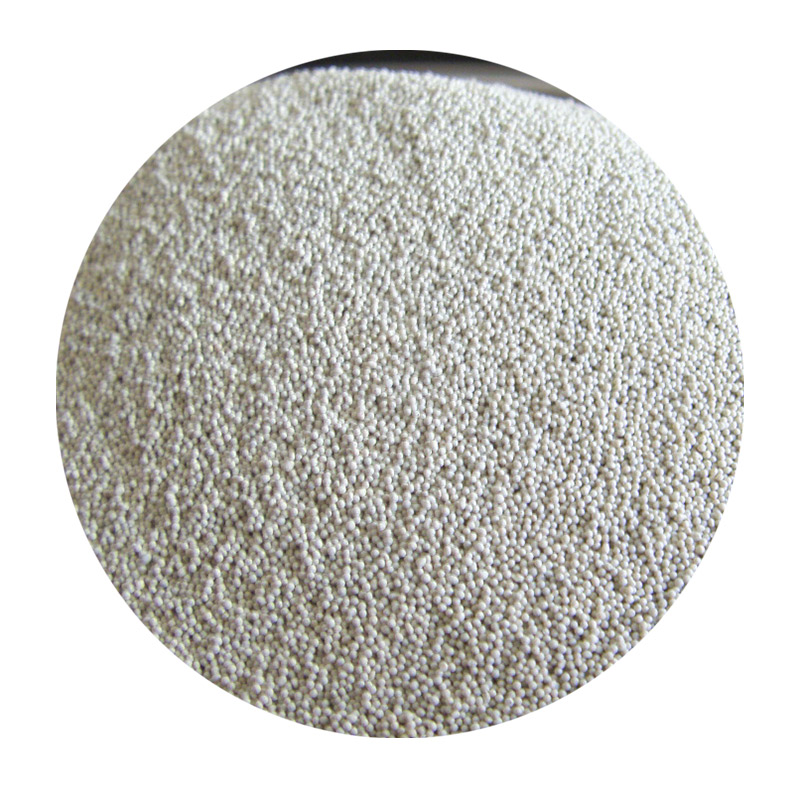

sand sintering

6. Finishing After cooling, additional finishing processes may be employed, such as grinding or coating, to achieve the desired surface quality and performance characteristics.

Applications of Sand Sintering

Sand sintering serves numerous applications across various industries

- Construction The most recognized application is in the production of construction materials like bricks, tiles, and precast concrete. Sand-sintered products boast excellent compressive strength and weather resistance, making them ideal for building structures.

- Art and Design Artists and designers utilize sand sintering to create unique sculptures and decorative items. The versatility of sand allows for creative freedom and the ability to produce detailed patterns and textures.

- Industrial Components Certain industries require specialized components that can withstand high temperatures and corrosive environments. Sand sintering can produce parts that meet these specifications, making it valuable in sectors such as aerospace and automotive.

Benefits of Sand Sintering

One of the most significant advantages of sand sintering is its eco-friendliness. The process largely uses natural silica sand and often minimizes waste. Additionally, energy consumption is reduced compared to other manufacturing processes, as sintering requires less heat than melting materials entirely.

Moreover, the resulting products exhibit excellent mechanical properties, such as high strength and durability. The ability to customize shapes and properties through the choice of additives and binders further enhances the attractiveness of sand sintering.

Conclusion

Sand sintering represents a crucial intersection of materials science, engineering, and art. It harnesses the unique properties of sand to create durable products across various sectors, from construction to fine art. As the world increasingly shifts toward sustainable manufacturing practices, the significance of sand sintering is likely to grow, making it an area of continued research and development. As industries strive for efficiency and sustainability, understanding and innovating within the realm of sand sintering will undoubtedly play a pivotal role in the future of materials science.

Post time:Januari . 02, 2025 01:19

Next:Kolik stojí pískové odlévání a jaké faktory to ovlivňují?