The Importance of Industrial Sand Casting in Modern Manufacturing

Industrial sand casting, a key process in modern manufacturing, plays a crucial role in the production of complex metal components. This method involves pouring molten metal into a sand mold, which forms the desired shape upon solidification. Sand casting is revered for its versatility and cost-effectiveness, making it an attractive choice for industries ranging from automotive to aerospace.

One of the significant advantages of sand casting is its ability to create intricate designs. The process uses a mixture of sand, clay, and water to form molds that can capture fine details and complex geometries. This capability is particularly beneficial in industries that demand precision components, such as the production of engine blocks, cylinder heads, and other vital engine parts. Furthermore, the molds can be easily modified, allowing manufacturers to adapt to design changes quickly without significant downtime or costs.

Another noteworthy benefit of industrial sand casting is its scalability. The process is suitable for both low and high-volume production runs. Small workshops can produce limited runs of specialized parts, while larger foundries can cater to mass production needs. The flexibility inherent in sand casting allows businesses to respond effectively to market demands, ensuring they can scale operations as needed.

Cost efficiency is another critical aspect of sand casting. The materials involved—primarily sand and metal—are relatively inexpensive compared to other casting methods. Additionally, the energy requirements for sand casting are lower than processes such as die casting or investment casting. This makes sand casting an ideal choice for manufacturers looking to maintain quality while minimizing production costs.

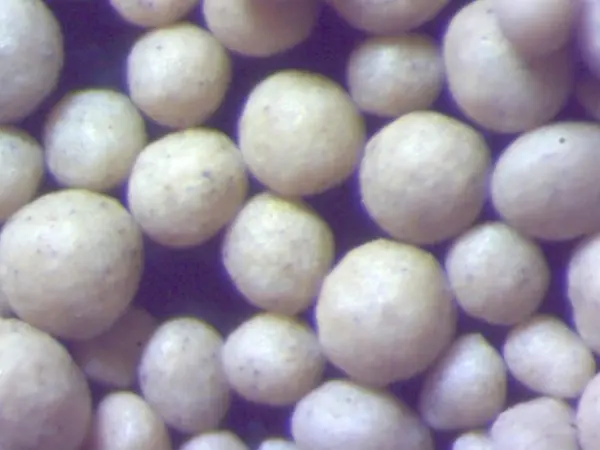

industrial sand casting

Moreover, sand casting can accommodate a wide range of metals, including aluminum, iron, and steel. This versatility enables manufacturers to select the best material for their specific application, ensuring that the final product meets both performance and durability standards. By using different metal alloys, manufacturers can optimize properties like strength, corrosion resistance, and weight, which are vital for various applications in demanding environments.

Despite its advantages, industrial sand casting does come with challenges. One primary concern is the surface finish of the cast parts, which is generally rougher compared to those made using other casting techniques. This can necessitate additional processing steps such as machining or polishing, which can increase lead times and costs. However, advancements in sand casting technologies, including the use of resin-bonded sands and improved mold-making techniques, have significantly enhanced the quality of cast products, minimizing the need for extensive secondary operations.

Environmental considerations are becoming increasingly important in industrial processes, and sand casting is no exception. While traditional methods can generate significant waste, innovations in sand recycling and mold reusability are creating more sustainable practices. Foundries are now exploring ways to repurpose used sand and reduce overall material consumption, aligning with global efforts to minimize environmental footprints.

In conclusion, industrial sand casting remains a cornerstone of modern manufacturing, providing a blend of flexibility, cost-effectiveness, and capabilities to produce complex metal components. Innovations in this field continue to evolve, ensuring that sand casting adapts to changing industry needs while addressing environmental concerns. As we advance, the significance of sand casting in supplying critical parts across various sectors will only continue to grow, solidifying its status as an indispensable manufacturing technique.

Post time:Septemba . 22, 2024 16:40

Next:resin with sand