Understanding How Sand Casting Works

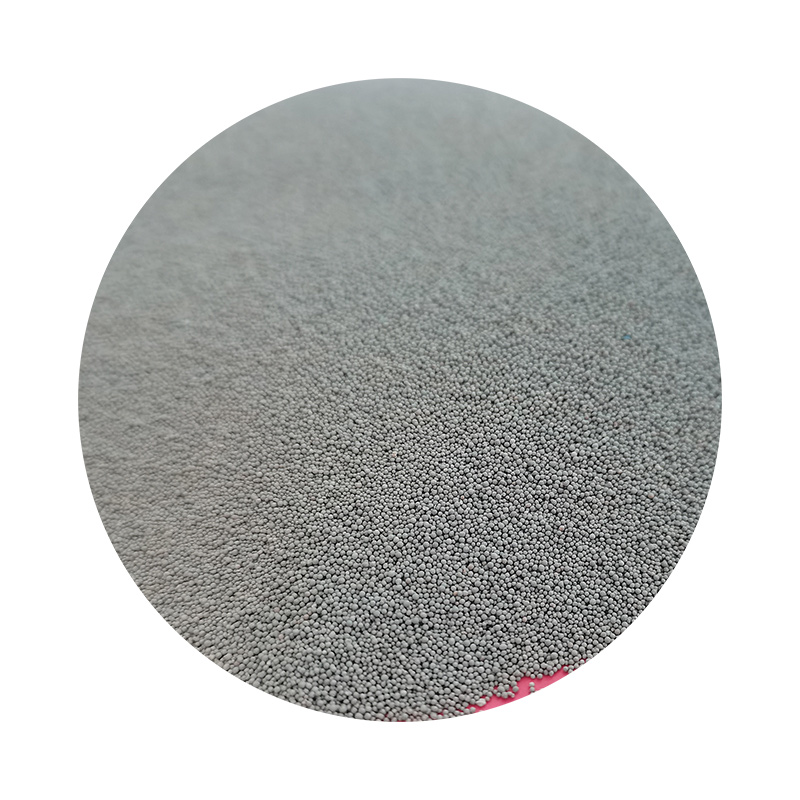

Sand casting, one of the oldest metal casting methods, has been used for centuries to create intricate metal parts and components. This process is essential in various industries, including automotive, aerospace, and machinery. The core principle behind sand casting is relatively straightforward, involving the use of sand to create molds that shape molten metal into desired forms.

Understanding How Sand Casting Works

After the mold is formed, the next step is to remove the pattern, leaving a hollow cavity. This cavity will be filled with molten metal. To ensure the mold can withstand the heat and pressure of the molten metal, it is often baked or treated to enhance its strength. Vent holes may also be created to allow gases to escape during the pouring process.

how sand casting works

Once the mold is prepared and the metal source selected, the metal is heated to its melting point. Common materials for sand casting include aluminum, iron, and bronze, which are melted in a furnace. When the metal reaches the desired temperature, it is poured into the mold cavity. Care must be taken to pour the metal smoothly to avoid defects caused by turbulence.

As the metal cools and solidifies, it takes on the shape of the mold. Cooling times vary depending on the thickness and size of the casting. Once the metal has cooled sufficiently, the mold is broken apart to reveal the cast part. This phase may involve shaking or knocking the mold, ensuring the finished piece can be removed without damage.

The final step in the sand casting process is finishing. This involves cleaning the casting to remove any sand residue and may include machining to achieve precise dimensions. Additional processes such as polishing or coating can be applied based on the end-use requirements of the product.

In conclusion, sand casting is a versatile and effective manufacturing process that allows for the creation of complex shapes with relatively low costs and materials. Its enduring popularity speaks to its ability to meet the needs of various industries, combining tradition with modern techniques for efficient production.

Post time:Oktoba . 12, 2024 01:26

Next:iron sand casting