The Cost of Sand Casting A Comprehensive Overview

Sand casting is a widely used metal casting process that involves the use of sand as the mold material. It is popular due to its versatility, relatively low cost, and ability to produce complex shapes. However, the actual cost of sand casting can vary significantly based on several factors, including the type of materials used, the complexity of the design, and the volume of production.

Material Costs

The costs associated with the materials used in sand casting are a significant factor. The primary material, sand, is relatively inexpensive—especially compared to metals like aluminum, bronze, and iron. However, additional materials such as binding agents, coatings, and additives can increase the overall cost. The exact material choice will depend on the desired properties of the final product, which may influence pricing.

Labor Costs

Labor costs can also vary widely, depending on the location of the foundry and the skill level of the workforce. In regions with higher labor costs, such as Western countries, the total cost may be elevated. Conversely, outsourcing to countries with lower labor costs can make sand casting more economical. Skilled labor is crucial for achieving high-quality casts, so investing in experienced professionals is always a worthwhile consideration.

how much does sand casting cost

Complexity and Design

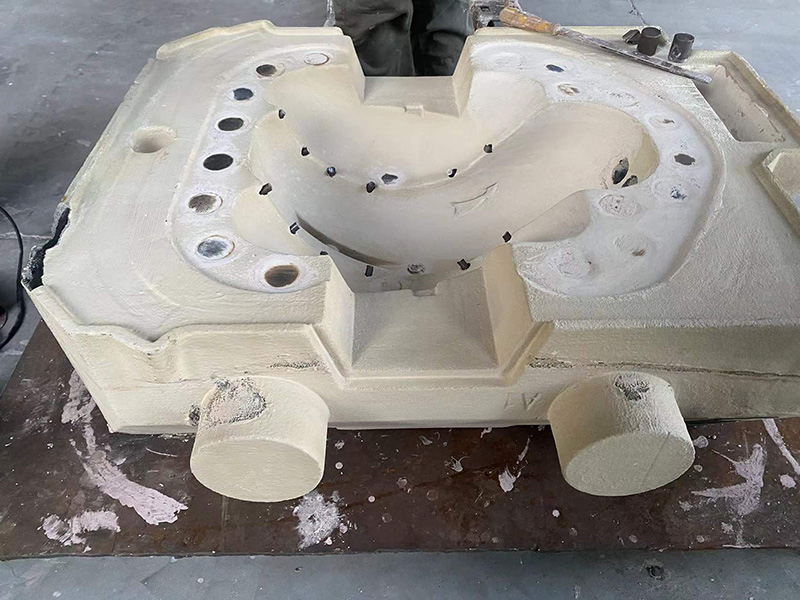

The complexity of the part being produced has a direct impact on the cost of sand casting. Intricate designs that require detailed molds can increase costs due to the additional time and skill involved in mold creation. Furthermore, complex designs may necessitate more sophisticated processing, which can lead to higher production costs. Simple parts, on the other hand, can be produced more quickly and affordably, making them a more cost-effective option.

Production Volume

The production volume plays a significant role in determining the cost per unit in sand casting. Higher production volumes usually lead to lower costs per part due to the economies of scale. For large runs, initial setup costs can be spread across many units, significantly reducing the cost per item. However, for low-volume production, the setup costs may make each unit more expensive.

Conclusion

In summary, the cost of sand casting is influenced by various factors, including material choice, labor expenses, design complexity, and production volume. While sand casting can be a cost-effective manufacturing technique, it is essential for businesses to evaluate their specific needs and conduct a thorough cost analysis. By understanding these variables, companies can better plan their budgets and make informed decisions about their casting processes, ultimately leading to successful production outcomes.

Post time:Oktoba . 10, 2024 10:48

Next:Applications of Resin Coated Sand in Modern Industries and Manufacturing Processes