The Rise of China’s Sand Casting Industry A Comprehensive Overview

China has emerged as a global leader in various manufacturing sectors, and among them, the sand casting industry holds a significant position. Sand casting, a process that involves creating a mold from sand to produce metal parts, has been a traditional yet vital method in the manufacturing of durable and complex components. As industries worldwide seek reliable and cost-effective solutions, Chinese sand casting factories have become a preferred choice for many.

Overview of Sand Casting

Sand casting, also referred to as sand mold casting, is one of the oldest methods of metal casting. The process involves creating a mold from a mixture of sand, clay, and water, into which molten metal is poured. Once the metal cools and solidifies, the mold is broken away to reveal the final product. This technique offers several advantages, including the ability to produce large parts with intricate designs, versatility in metal alloys, and cost-effectiveness for both small and large production runs.

Factors Contributing to China’s Dominance

Several key factors contribute to China's dominance in the sand casting industry

1. Cost-Effective LaborChina’s labor force is significantly cheaper compared to many Western countries. This enables factories to keep production costs low, making it an attractive location for companies looking to minimize expenses without compromising quality.

2. Advanced Technology Chinese manufacturers have rapidly adopted modern casting technologies. With investments in state-of-the-art machinery, including automated sand casting equipment, they have increased capability and efficiency while reducing defects and waste.

3. Vast Raw Material Resources China has abundant natural resources, including silica sand, which is a primary raw material for sand casting. The availability of local materials reduces shipping costs and lead times, further enhancing competitiveness.

4. Government Support The Chinese government has been supportive of manufacturing industries through favorable policies and incentives that promote investment in technology and infrastructure development, aiding growth in the sand casting sector.

5. Strong Supply Chain Network China boasts a robust supply chain network that facilitates smooth logistics, quick turnaround times, and efficient sourcing of materials. This network enables sand casting factories to respond swiftly to market demands and customer needs.

china sand casting factory

Applications of Sand Casting in China

The applications of sand casting are vast and span multiple industries, including automotive, aerospace, machinery, and construction. In the automotive sector, for example, sand casting is extensively used to manufacture engine blocks, cylinder heads, and transmission cases. The aerospace industry benefits from sand casting for producing intricate components that meet stringent regulatory standards.

Moreover, sand casting is increasingly used in the production of custom parts and prototypes. As businesses embrace the push towards faster product development, the ability to quickly create sand molds has made it a sought-after method for rapid prototyping.

Challenges Facing the Industry

Despite its success, the Chinese sand casting industry faces several challenges

1. Environmental Concerns Sand casting can be resource-intensive and may produce emissions, leading to stricter environmental regulations. Factories must invest in eco-friendly technologies to comply with these regulations.

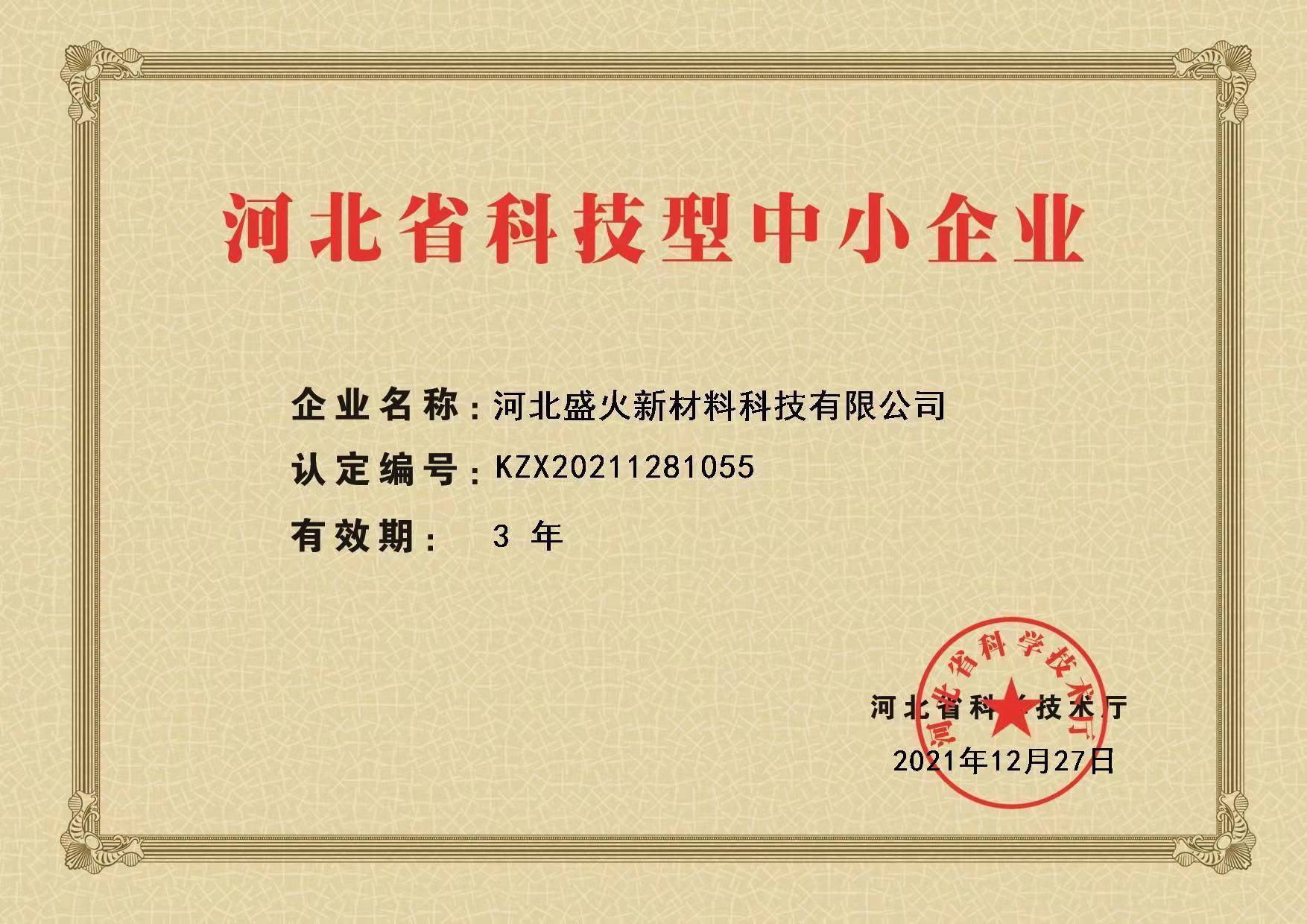

2. Quality Control With numerous manufacturers in the market, ensuring consistent quality across different factories can be a challenge. Adopting international quality standards and certifications can help mitigate this issue.

3. Rising Labor Costs As the economy grows, labor costs in China are beginning to rise. This could impact the future competitiveness of the industry unless manufacturers continue to innovate and improve efficiency.

Conclusion

The sand casting industry in China has established itself as a key player in the global manufacturing landscape. With its combination of cost efficiency, advanced technology, and robust supply chains, Chinese sand casting factories are well-positioned to meet the growing demand for quality metal parts. However, addressing environmental concerns and maintaining stringent quality control will be essential for sustaining growth in this evolving sector. As industries around the world continue to rely on sand casting for their manufacturing needs, China's factories will remain at the forefront of this age-old craft, blending tradition with modern practices to forge a competitive future.

Post time:Oktoba . 12, 2024 03:00

Next:is sand casting sustainable