Should You Sand 3D Prints? A Comprehensive Guide

3D printing has revolutionized the way we create and design objects. However, once a print has been completed, many makers find themselves faced with the question should I sand my 3D prints? The answer is not as straightforward as it may seem, as it depends on several factors including the material used, the desired finish, and the purpose of the print. In this article, we will explore the considerations for sanding 3D prints and provide tips to achieve the best results.

Understanding the Need for Sanding

Most 3D prints, especially those made with Fused Deposition Modeling (FDM) technology, have a distinct layer-by-layer texture. While this can be aesthetically pleasing for certain projects, there are situations where a smoother finish is desirable. If your print is intended for functional use or as a display piece, sanding might enhance its appearance and performance. It is essential to evaluate the final application of your print when deciding whether to sand.

Types of Materials and Their Sanding Properties

Different 3D printing materials respond to sanding in varied ways. For example, PLA (Polylactic Acid) is a common material for 3D prints and is relatively easy to sand. Sanding PLA can significantly improve its finish since it is less prone to melting under heat. Conversely, ABS (Acrylonitrile Butadiene Styrene) can also be sanded, but it has a higher tendency to warp if not carefully treated—thus, sanding should be approached with caution.

For materials like PETG (Polyethylene Terephthalate Glycol) and Nylon, sanding can be more challenging due to their toughness and resistance to abrasion. These materials may require higher abrasive tools or techniques to achieve the desired smoothness. Therefore, understanding your material is crucial before proceeding with the sanding process.

Techniques for Sanding 3D Prints

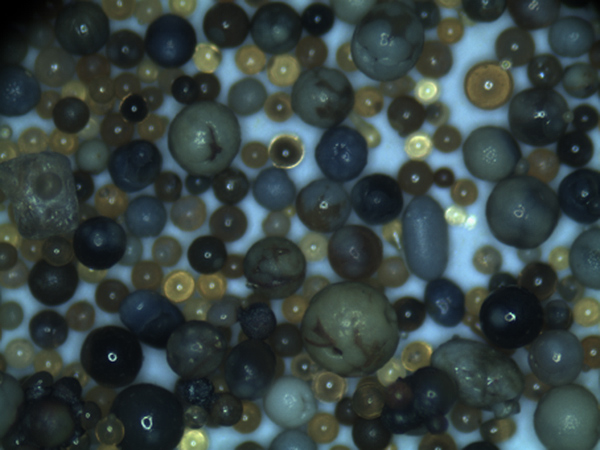

should you sand 3d prints

If you've determined that sanding is the right choice for your print, here are some effective techniques

1. Use the Right Grit Start with a coarser grit sandpaper (around 100-150) to remove any significant imperfections, and then progress to finer grits (up to 400 or higher) to achieve a smoother surface. Always sand in a circular motion to avoid creating flat spots.

2. Wet Sanding This technique involves using water or lubricants while sanding. Wet sanding helps reduce dust and minimizes the risk of overheating the material which could lead to melting. It also results in a smoother finish.

3. Tools Manual sanding with sandpaper is common, but power tools like rotary sanders or Dremels can make the process faster, especially for larger prints. However, they require a gentle touch to avoid excessive heat buildup that can damage the print.

4. Post-Sanding Finish After sanding, consider additional finishing techniques, such as priming and painting, which could enhance the appearance of your print further. Using a few layers of primer followed by paint can create a professional-looking finish.

Conclusion

Sanding 3D prints is not always necessary, but it can dramatically improve an object's aesthetic and functional qualities when done correctly. If you are looking to refine your prints for better presentation or performance, understanding the materials, selecting the proper techniques, and using the right tools will contribute to a successful outcome. However, it's important to recognize that not all prints need to be sanded, and sometimes the texture of the print may suit the project perfectly.

In summary, whether to sand your 3D prints depends on your goals. With a careful approach, sanding can transform your 3D prints from basic models to polished works of art, enhancing both their look and feel while often improving their usability.

Post time:нов . 11, 2024 12:45

Next:g2 super sand