Understanding the Role of Resin Coated Sand Manufacturers in the Foundry Industry

Resin coated sand has become an essential material in the foundry industry, known for its superior quality and performance in metal casting processes. This innovation is a result of advanced manufacturing techniques that enhance the bonding and strength of sand molds. The role of resin coated sand manufacturers is crucial as they provide the raw materials that serve as the backbone of modern foundry operations.

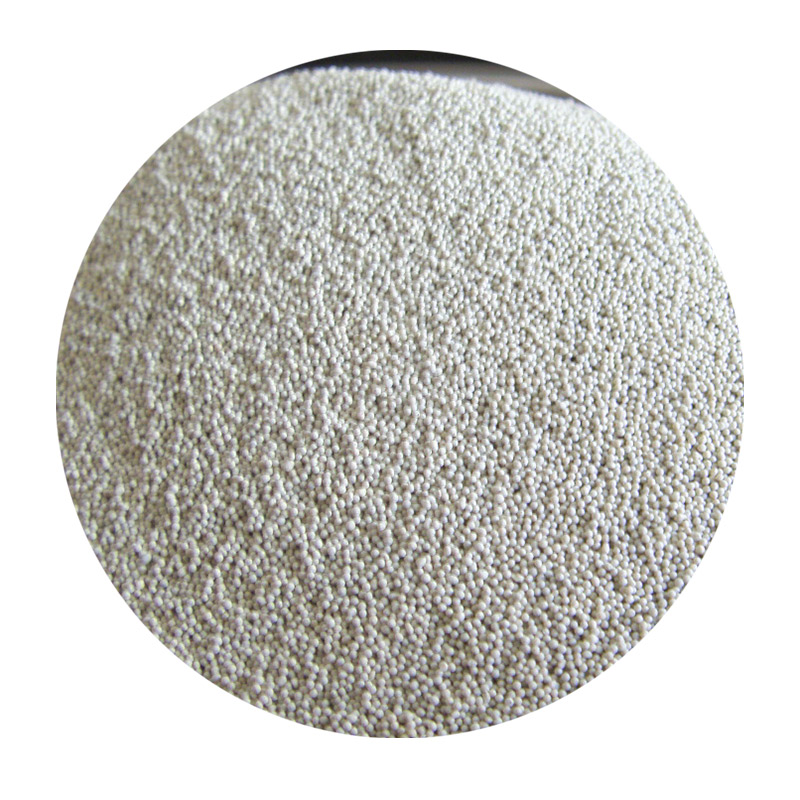

The primary function of resin coated sand is to create a sustainable mold that can withstand high temperatures and the pressure exerted during the pouring of molten metal. Manufacturers typically coat high-quality silica sand with a thermosetting resin, which hardens upon heating. This process transforms the sand into a reliable mold material capable of reproducing intricate designs while maintaining dimensional accuracy.

One of the primary advantages of resin coated sand is its ability to provide a smooth surface finish. This is particularly important for industries producing complex components where surface integrity is key. The fine texture of the resin coated sand reduces the need for extensive post-casting operations, which further streamlines production timelines and reduces costs.

resin coated sand manufacturers

The market for resin coated sand has witnessed substantial growth due to the increasing demand for high-performance materials in foundry applications. Key sectors such as automotive, aerospace, and heavy machinery rely heavily on resin coated sand for producing various components. Consequently, manufacturers are continuously innovating their processes to improve the quality and performance of the resin coated sand, leading to enhanced durability and lower environmental impact.

Sustainability is an essential consideration in the foundry industry today. As resin coated sand manufacturers strive to adopt eco-friendly practices, many are exploring the use of recycled materials and biodegradable resins. This shift not only helps in reducing waste but also lowers the carbon footprint associated with traditional sand casting methods.

Moreover, the competitive landscape of resin coated sand manufacturing requires companies to maintain high standards of quality while optimizing production efficiency. The ability to customize sand mixtures according to specific client requirements is a significant factor in establishing long-term relationships with foundries. Manufacturers that can offer tailored solutions are often more successful in meeting the diverse needs of the market.

In conclusion, the role of resin coated sand manufacturers is pivotal to the efficiency and effectiveness of the foundry industry. Their continuous innovation, commitment to sustainability, and ability to cater to specific market demands underscore their importance. As technology advances, one can expect further enhancements in resin coated sand formulations, ultimately leading to more efficient production processes and superior casting outcomes.

Post time:сеп . 03, 2024 00:57

Next:Steel Sand Casting - Precision Casting Solutions for Durable Products