Understanding Lost Foam Castings An Innovative Manufacturing Process

Lost Foam Casting (LFC) is a modern manufacturing technique that has gained popularity due to its ability to produce complex geometries with high precision and lower production costs. This method combines the principles of traditional casting with advanced technology, making it an appealing choice for many industries, particularly in automotive and aerospace applications.

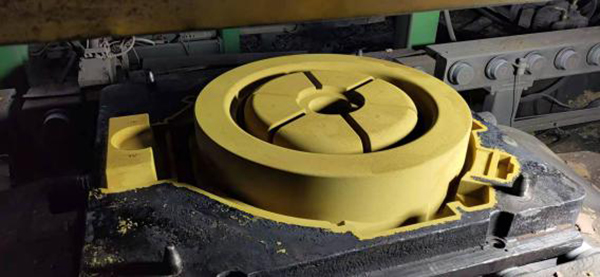

At the core of the lost foam casting process is the use of an expendable foam pattern. The process begins with the creation of a foam model that represents the final shape of the metal part. This model is typically made from polystyrene foam, which is lightweight and easy to shape. The foam pattern is then coated with a ceramic material to create a shell around it. This shell provides necessary strength during the casting process.

Once the foam pattern is prepared and coated, it is placed in a sand mold. The sand used in this process is specially formulated to handle the high temperatures of molten metal while allowing for the foam to vaporize. After the mold is assembled, molten metal is poured into the cavity. As the metal fills the mold, the heat causes the foam pattern to vaporize, leaving behind a cavity that perfectly matches the shape of the original foam model. This unique aspect of the LFC process eliminates the need for complex core designs often required in traditional casting methods.

lost foam castings

One of the significant advantages of lost foam castings is its ability to create intricate and detailed features without the need for additional machining

. This reduction in secondary operations not only speeds up production but also results in lower overall costs. Additionally, since parts can be cast directly to net shape, there is minimal material waste, making it an environmentally friendly option compared to other casting methods.The versatility of the lost foam casting process allows for a wide range of materials to be used, including aluminum, iron, and even some specialty alloys. This flexibility opens the door for manufacturers to create components for various applications, from engine blocks to artistic sculptures. Furthermore, the ability to produce complex geometries means that manufacturers can meet the increasingly demanding specifications of modern engineering designs.

However, while lost foam casting offers numerous benefits, there are also challenges associated with the process. Controlling the quality of the foam patterns is critical, as defects in the pattern can lead to problems in the final casting. Moreover, the setup cost can be significant for low-volume production runs, which might make it less appealing for smaller manufacturers.

In conclusion, lost foam casting is a transformative manufacturing process that blends tradition with innovation. Its capacity to produce high-precision, complex parts with reduced material waste makes it a valuable technique in modern manufacturing. As industries continue to evolve and demand increasingly sophisticated components, the relevance of lost foam castings is sure to expand in the years to come. With ongoing advancements in materials and technology, the future looks bright for this efficient casting method.

Post time:окт . 07, 2024 06:55

Next:metal sand casting process