Investment Casting vs. Sand Casting A Comparative Analysis

When it comes to metal casting, two of the most widely used processes are investment casting and sand casting. Each method has its own unique characteristics, advantages, and limitations, and selecting the right one often depends on the specific requirements of a project. Understanding the differences between these two casting techniques can help businesses make informed decisions regarding cost, complexity, and quality of the final product.

Investment Casting vs

. Sand Casting A Comparative AnalysisOn the other hand, sand casting is one of the oldest and most traditional forms of casting. This process uses a mixture of sand, clay, and water to create a mold. The sand is packed around a pattern of the object to be cast, and once the pattern is removed, molten metal is poured into the mold. Sand casting is known for its versatility and ability to produce large parts, but it generally results in a rougher surface finish compared to investment casting. It's widely used in industries like construction and power generation, where large components are often required.

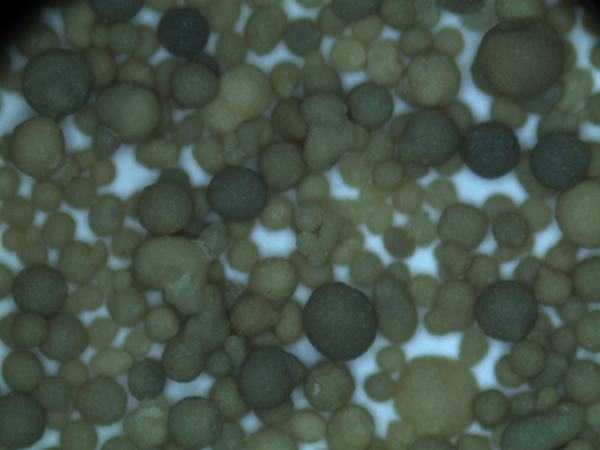

investment vs sand casting

One significant factor to consider when choosing between investment casting and sand casting is the cost. Investment casting typically involves higher initial setup costs due to the complexity of creating molds and the need for specialized equipment. However, it can be more cost-effective for small production runs of intricate parts, as the high precision can reduce the need for extensive machining after the casting process. In contrast, sand casting is more economical for large batch productions and simpler geometries, as its setup is relatively straightforward.

Another aspect that sets these two processes apart is lead time. Investment casting can take longer, especially for complex designs that require multiple steps in the mold-making process. Conversely, sand casting often has a quicker turnaround time, making it suitable for projects with tighter deadlines.

In summary, both investment casting and sand casting have their own sets of advantages and challenges. Investment casting excels in producing detailed and precise parts but comes with higher initial costs and lead times. Sand casting is more cost-effective for larger runs and less complex shapes, but it does not offer the same level of precision. Ultimately, the choice between these two methods should align with the specific requirements of the project, including budget, production volume, and desired quality. By carefully weighing these factors, companies can enhance their manufacturing processes and achieve better outcomes.

Post time:окт . 18, 2024 13:41

Next:Comparing Sand Casting and Permanent Mold Casting Methods and Their Applications