The Importance of Quality Casting Sand Suppliers in the Foundry Industry

Casting sand is a critical component in the foundry industry, playing a vital role in the production of metal castings. The properties of the sand used in the casting process can significantly influence the quality of the final product. Thus, selecting the right casting sand supplier is essential for any foundry looking to achieve consistent results, reduce costs, and enhance productivity.

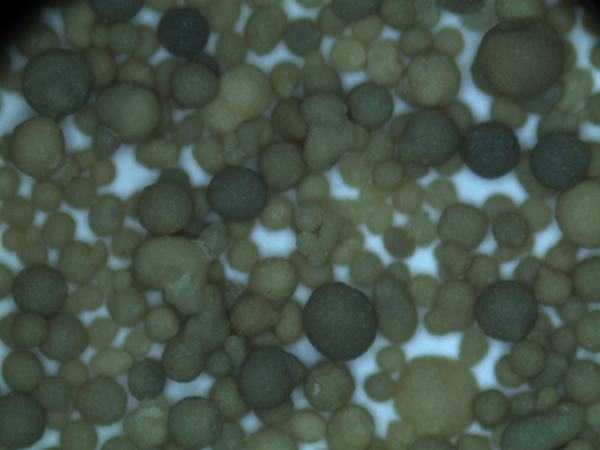

Understanding Casting Sand

Casting sand, primarily made up of silica, is used to create molds and cores for casting metals. The most common type of casting sand is silica sand, due to its availability and desirable properties such as high melting point, resistance to thermal shock, and good permeability. The quality of sand can affect various aspects of the casting process, including the surface finish of the product, the accuracy of dimensions, and the overall mechanical properties of the cast metal.

The Role of Suppliers

Quality casting sand suppliers provide not just the raw material but also the technical support necessary for optimizing the casting process. A reputable supplier will offer a variety of sand grades, each tailored for specific applications. For instance, finer sands may be suitable for detailed work, while coarser sands may be used for larger castings that do not require fine detail.

Moreover, suppliers often include additives and binders to enhance the performance of the sand. These can improve bond strength, reduce dust emissions during handling, and even alter the thermal properties of the sand, resulting in better casting outcomes. A supplier's ability to deliver customized solutions is a significant benefit to foundries, as it allows them to meet specific project requirements.

Quality Assurance and Consistency

casting sand suppliers

When selecting a casting sand supplier, it is essential to consider their quality assurance processes. Consistency in sand properties between batches is crucial, as variability can lead to defects in the casting process. Leading suppliers will implement rigorous testing procedures to ensure that the sand meets industry standards and customer specifications. This includes testing for grain size distribution, shape, and chemical composition to ensure that the sand performs as expected in specific casting applications.

The Economic Impact

In addition to quality, the economic aspect of sourcing casting sand cannot be overlooked. Foundries must balance the cost of materials with the impact on production efficiency and quality. A reliable supplier can help foundries minimize waste and optimize sand usage, ultimately reducing costs. Investing in quality materials may appear more expensive upfront, but the long-term savings from improved yield and reduced defects can be substantial.

Building Relationships

Finally, establishing a strong relationship with a casting sand supplier can be beneficial for foundries. Suppliers who understand a foundry's specific needs can offer valuable insights and recommendations, helping to improve processes and outcomes. Regular communication and feedback can lead to continuous improvement and innovation in the casting process.

Conclusion

In conclusion, the choice of casting sand suppliers is pivotal for the success of any foundry. Quality materials, combined with technical support and consistent supply, can significantly enhance production capabilities. As the industry continues to evolve, partnering with reliable suppliers will be key to maintaining a competitive edge in the challenging landscape of metal casting. Investing time and resources in finding the right casting sand supplier is a step toward achieving excellence in the foundry industry.

Post time:сеп . 11, 2024 05:23

Next:Tests de sable de fonderie - Analyse et solutions de qualité