Sand Casting Applications A Versatile Manufacturing Technique

Sand casting, one of the oldest and most widely used manufacturing processes, has found applications across various industries due to its unique advantages. This method, which involves creating a mold from sand to produce metal parts, offers flexibility, cost-effectiveness, and the ability to handle complex geometries. As we delve into the various applications of sand casting, it's essential to understand its significance in manufacturing today.

Overview of Sand Casting Process

The sand casting process involves several key steps. First, a pattern, typically made from metal or other sturdy materials, is created in the form of the desired end product. This pattern is then placed in a mixture of sand and binder, forming a mold that will hold the molten metal. Once the mold is prepared, the molten metal is poured into it and allowed to cool and solidify. After the cooling process, the sand mold is broken away, revealing the finished casting.

Applications in Various Industries

1. Automotive Industry One of the largest users of sand casting is the automotive industry. Components such as engine blocks, transmission housings, and crankshafts are often produced using this technique. The ability to create large, complex parts with excellent dimensional accuracy and surface finish makes sand casting an ideal choice for automotive manufacturers. Moreover, sand casting allows the use of various alloys, which can enhance the performance and durability of automotive components.

2. Aerospace Sector In aerospace, sand casting is used to manufacture critical components that demand high strength and lightweight properties. Parts like turbine casings and brackets are often cast using sand because of the intricate designs and the high-performance materials required. The versatility in creating complex shapes with precision makes sand casting particularly advantageous for aerospace applications where weight reduction is paramount.

3. Heavy Machinery and Equipment The heavy machinery sector heavily relies on sand casting for producing large components like frames and gears. Sand casting allows for the creation of large, robust parts that can withstand the rigors of heavy-duty applications. This process is particularly beneficial for manufacturers of construction equipment, agricultural machinery, and mining equipment.

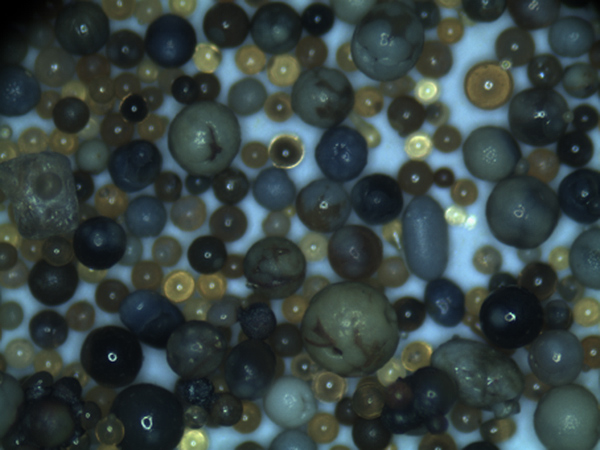

sand casting applications

4. Art and Sculpture Beyond industrial applications, sand casting also plays a significant role in art and sculpture. Artists utilize sand casting to create intricate metal sculptures and decorative pieces. The process allows for innovative designs that can be duplicated many times, making it a preferred method for replicating artwork without losing detail.

5. Marine Applications The marine industry employs sand casting for various parts, including propellers and engine components. Due to the harsh conditions of marine environments, these components must be made from corrosion-resistant materials, which can be efficiently created using sand casting. The ability to produce complex shapes and large parts makes it ideal for manufacturing components that require both strength and precision in marine applications.

Advantages of Sand Casting

Sand casting offers several benefits that make it a favorable choice for many applications. Firstly, it is highly economical, especially for low to medium production volumes. The materials required for creating sand molds are relatively inexpensive compared to other casting methods. Additionally, the flexibility of sand casting allows for the use of different metal alloys, thus accommodating a wide range of mechanical properties and specifications.

Secondly, the ability to create large and complex shapes is a significant advantage of this process. Many modern designs demand intricate geometries that are challenging to achieve with other manufacturing techniques. Sand casting's adaptability to changing designs makes it a robust solution for industries that frequently update their product lines.

Lastly, sand casting has a relatively simple setup and shorter lead times compared to more advanced casting techniques. This benefits manufacturers who need to produce parts quickly and efficiently, maintaining a competitive edge in the market.

Conclusion

In conclusion, sand casting remains a relevant and widely utilized manufacturing process due to its versatility and cost-effectiveness. Its applications span numerous industries, from automotive to aerospace and art. As technology advances, innovations in sand casting techniques will likely continue to enhance the quality, efficiency, and possibilities offered by this age-old method, ensuring its place in modern manufacturing for years to come.

Post time:Nën . 19, 2024 11:40

Next:sand casting history