Resin Bonded Sand Casting A Comprehensive Overview

Resin bonded sand casting is a modern and highly efficient casting method that has gained widespread acceptance in various industries, including aerospace, automotive, and general manufacturing. This process involves the use of a resin binder mixed with sand to create molds that can withstand high temperatures and provide excellent surface finishes for metallic castings. In this article, we will explore the advantages, applications, and the steps involved in resin bonded sand casting.

Advantages of Resin Bonded Sand Casting

One of the primary advantages of resin bonded sand casting is the superior dimensional accuracy it offers. The resin bonding agents enhance the strength of the mold, allowing for intricate shapes and designs to be achieved with high precision. This results in a tighter tolerance in the final cast products, which is critical for components that must fit together seamlessly.

Another significant benefit is the excellent surface finish. The smoothness of the resin-bonded molds reduces the need for extensive post-casting machining, which not only saves time but also reduces production costs. Additionally, since the molds can capture fine details, they result in less wasted material and reduced scrap rates.

Moreover, resin bonded sand casting can support faster production cycles. The curing process of the resin allows for quick setting times, enabling manufacturers to produce molds more rapidly than traditional sand casting methods. This efficiency is essential in competitive markets where time-to-market can determine success.

Applications of Resin Bonded Sand Casting

Resin bonded sand casting finds applications across various sectors. In the automotive industry, it is used to manufacture engine blocks, transmission cases, and other critical components that require high strength and durability. The aerospace industry also takes advantage of this method for producing complex parts that need to withstand extreme conditions.

Beyond transportation, resin bonded sand casting is employed in the production of consumer goods, industrial equipment, and even artistic sculptures. The versatility of the process allows for the casting of both ferrous and non-ferrous metals, making it suitable for a diverse range of applications.

resin bonded sand casting

The Process of Resin Bonded Sand Casting

The resin bonded sand casting process involves several key steps

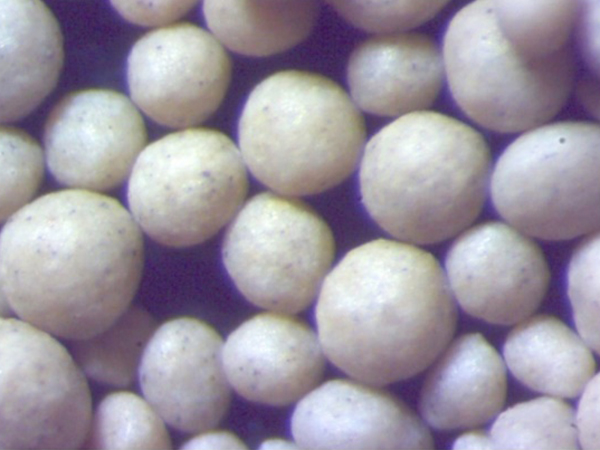

1. Preparation The first step is to mix the sand with the resin binder and hardening agents. This mixture must be homogenous to ensure the quality of the molds.

2. Mold Creation Once the sand is prepared, it is packed around a pattern (usually a metal pattern) to create the mold shape. The mixture is compacted to achieve the desired density.

3. Curing After the mold is formed, it is cured using heat or chemical activators. This step solidifies the mold and increases its strength.

4. Casting Once the mold is set, the molten metal is poured into it. The resin bonded sand mold provides a durable cavity to form the casting.

5. Cooling and Finishing After pouring, the metal is allowed to cool and solidify. Once cooled, the sand mold is broken away to reveal the finished casting. Any necessary finishing operations, such as machining and surface treatment, are then performed.

Conclusion

Resin bonded sand casting is an innovative process that enhances the traditional sand casting method by providing improved accuracy, finish, and production speed. Its ability to cater to various industries makes it an invaluable technique in modern manufacturing. As technology continues to advance, resin bonded sand casting is expected to evolve further, potentially incorporating new materials and processes that will enhance its capabilities even more. The future of this casting method looks promising, as it aligns with the industry's ongoing pursuit of efficiency and quality.

Post time:Dhj . 03, 2024 22:56

Next:Techniques for Sanding and Finishing 3D Printed Resin Models