The Importance of Sand Casting in Modern Manufacturing

Sand casting, one of the oldest and most versatile metal casting processes, serves as a critical component in the manufacturing industry today. Its significance can be noted across various sectors, from automotive to aerospace, and even in artistic applications. The importance of sand casting lies in its cost-effectiveness, adaptability, and ability to produce complex geometries, making it a preferred choice for many engineers and manufacturers.

Cost-Effectiveness

One of the most compelling reasons for the widespread use of sand casting is its cost-effectiveness. The raw materials required for sand casting—primarily sand, clay, and water—are relatively inexpensive and readily available. Unlike other casting methods, which may require costly molds made of metal, sand casting utilizes sand molds that can be easily formed and reused. This reduces the overall costs associated with mold-making and also minimizes waste materials. Furthermore, because sand casting supports a wide range of metals—from aluminum to iron—it allows manufacturers to produce components at a lower overall expense.

Adaptability

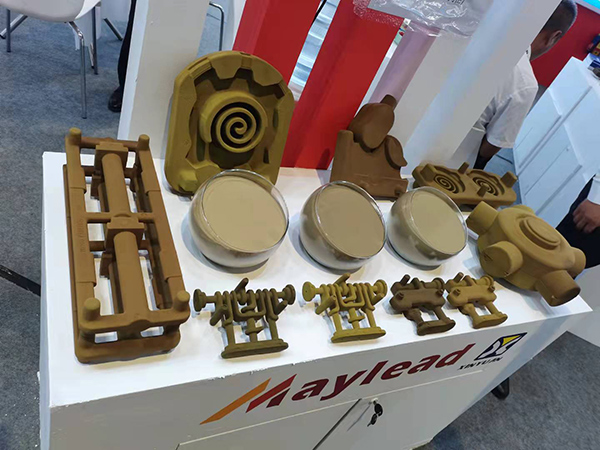

Sand casting is notable for its adaptability to various applications. It can accommodate a wide range of sizes and shapes, making it an ideal choice for both small and large production runs. This process allows for the casting of intricate designs, and because the sand mold can be formed easily by hand or machine, it gives designers considerable flexibility in creating unique products. Additionally, sand casting can be utilized for both ferrous and non-ferrous metals, thus expanding its applications in different industrial sectors.

Complex Geometries and Surface Finishes

importance of sand casting

The capability to produce complex geometries is another essential aspect of sand casting. In industries such as automotive and aerospace, components often need to be both lightweight and strong, with intricate shapes that traditional machining techniques might struggle to replicate. Sand casting can create these detailed designs with relative ease. After the casting process, various finishing techniques can be applied to achieve the desired surface quality, allowing for a high degree of customization. This versatility makes sand casting an invaluable technique for producing prototypes, as well as for low to medium production volumes.

Large-Scale Production

The sand casting process also supports large-scale production, an important factor for many industries. The ability to produce multiple molds rapidly allows for faster turnaround times and meets the demands of high-volume production. Modern advancements in sand casting technology, such as the development of automatic molding machines and improved sand mixtures, have further increased production efficiency. These innovations have enhanced the process's speed and reliability, ensuring high-quality outputs even when producing large batches.

Environmental Considerations

As manufacturing continues to face scrutiny over its environmental impact, sand casting offers some environmentally friendly advantages. The sand used in the casting process can often be reused multiple times, reducing material waste. Additionally, advancements in sand recycling technologies have made it easier to reclaim and reuse sand without compromising quality. This not only makes the process more sustainable but also lessens the ecological footprint of metal casting.

Conclusion

In conclusion, the importance of sand casting in modern manufacturing cannot be overstated. Its cost-effectiveness, adaptability to a wide range of applications, capability to produce complex designs, and support for large-scale production make it an essential method in various industries. As sustainability becomes a key focus, sand casting's ability to recycle materials and reduce waste further enhances its relevance. In a world increasingly seeking efficient and environmentally conscious manufacturing solutions, sand casting stands out as a timeless yet progressive option that is likely to remain pivotal in the future of industrial production.

Post time:Dec . 12, 2024 11:09

Next:golden sands prices