Understanding Resin Coated Sand Suppliers

In the world of manufacturing, particularly in the foundry industry, the importance of quality materials cannot be overstated. One such essential material is resin coated sand. This specialized sand is utilized predominantly in the production of metal castings, providing significant advantages over traditional methods. For businesses aiming for high precision and improved casting quality, finding reliable resin coated sand suppliers is crucial.

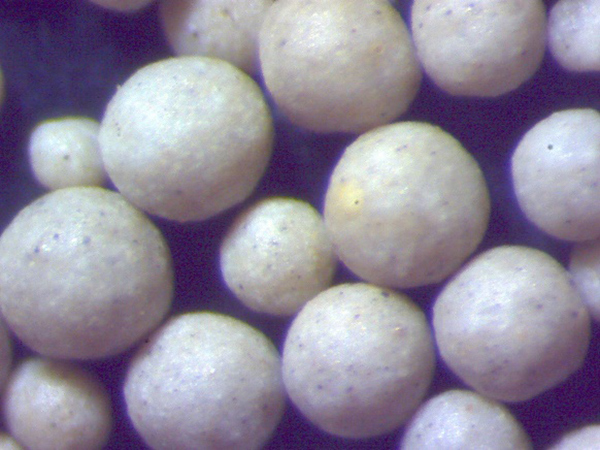

What is Resin Coated Sand?

Resin coated sand is composed of high-quality silica sand that has been treated with a thermosetting resin. This treatment enhances its properties, making it ideal for various casting applications. The resin immediately binds the sand particles together, allowing for better shape retention during the mold-making process. This feature is particularly valuable in complex casting designs, enabling manufacturers to produce intricate details with higher dimensional accuracy.

Benefits of Using Resin Coated Sand

One of the primary benefits of resin coated sand is its excellent strength and resistance to thermal deformation. This is especially important in applications involving high-temperature metals, which can otherwise lead to mold distortion with conventional sands. Additionally, the use of resin coated sand results in smoother surfaces on the final castings, reducing the need for extensive post-casting finishing processes.

Moreover, resin coated sand has a lower level of moisture absorption compared to traditional sands. This characteristic minimizes the risk of defects during casting, such as shrinkage or warping, further ensuring the integrity of the final product. As industries continue to strive for more efficient production processes, the demand for resin coated sand is on the rise, emphasizing the importance of sourcing it from reputable suppliers.

Choosing the Right Supplier

resin coated sand suppliers

When searching for resin coated sand suppliers, several factors should be considered

1. Quality of Product Ensure that the supplier offers high-quality resin coated sand that meets industry standards. Request product data sheets and certifications to verify the quality.

2. Customization Options Different applications may require specific sand characteristics. A good supplier should offer customization options to meet unique demands, including variations in grain size, resin type, and coating thickness.

3. Delivery and Logistics Timely delivery is crucial for maintaining production schedules. Evaluate suppliers based on their logistics capabilities and track record in fulfilling orders on time.

4. Technical Support A reliable supplier should provide technical assistance and guidance in optimizing the use of resin coated sand in your processes. This includes advice on mixture ratios, curing times, and mold-making techniques.

5. Cost-Effectiveness While quality should never be compromised, cost is also a key consideration. Compare prices from different suppliers but weigh them against the quality and services offered.

In conclusion, choosing the right resin coated sand supplier plays a critical role in the foundry industry. By understanding the properties and advantages of resin coated sand, along with the criteria for selecting a supplier, businesses can enhance their casting operations and achieve superior results. As the industry continues to evolve, partnering with the right suppliers will become even more important for maintaining competitiveness and meeting customer demands.

Post time:Oct . 12, 2024 12:27

Next:how accurate is sand casting