How to Sand Resin 3D Prints A Comprehensive Guide

Resin 3D printing has gained immense popularity for its ability to produce highly detailed and smooth prints compared to traditional FDM (Fused Deposition Modeling). However, post-processing resin prints often involves some level of sanding to achieve that perfect finish. In this article, we will guide you through the process of sanding resin 3D prints, ensuring you obtain a professional-looking result.

Why Sanding is Necessary

While resin printers can produce smooth surfaces straight out of the printer, the prints often still exhibit slight imperfections, layer lines, or surface textures due to the printing process. Sanding helps remove these imperfections and can also prepare the surface for painting or other finishing techniques. It’s an essential step for achieving that polished, high-quality appearance.

Tools and Materials Needed

To sand your resin prints effectively, you will need the following tools and materials

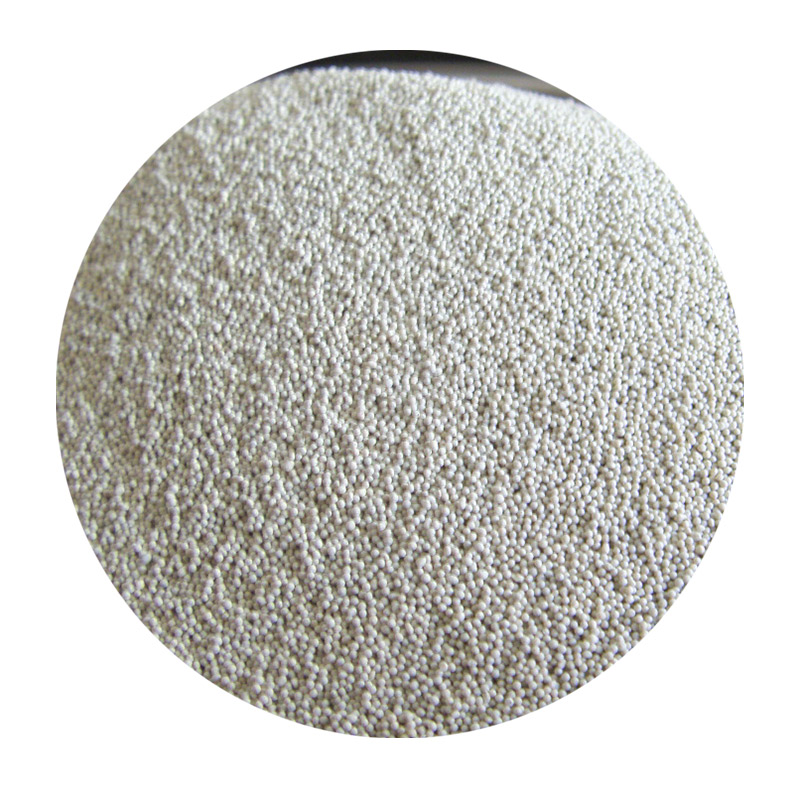

1. Sandpaper Use a range of grits, starting from coarse (around 120-220 grit) to fine (up to 1000 grit or higher). 2. Sanding Sponge These can conform better to the contours of your print, especially for intricate designs. 3. Water Wet sanding can minimize dust and reduce scratches. 4. Safety Gear Always wear gloves, a mask, and protective eyewear when sanding resin, as the dust can be harmful. 5. A Clean Workspace Keeping your workspace organized will make the process smoother and safer.

The Sanding Process

how to sand resin 3d prints

1. Cure Your Print Before sanding, ensure your print is fully cured. This means exposing it to UV light as per your resin's guidelines. An under-cured print can lead to issues while sanding.

2. Start with Coarse Grit Begin by using coarse sandpaper (120-220 grit) to remove any significant imperfections, layer lines, or support marks. Sand in a consistent motion, being careful not to apply too much pressure that could damage the print.

3. Progress to Medium Grit Once the major imperfections are smoothed out, switch to a medium grit sandpaper (400-600 grit). This step will help refine the surface further and continue to reduce scratches left by the coarse paper.

4. Wet Sanding If you're looking for an even smoother finish, wet sanding is highly effective. Dip your sandpaper in water and continue sanding. This technique helps to minimize dust and provides a smoother texture. It can also help keep the sandpaper from clogging.

5. Finish with Fine Grit Once you are satisfied with the appearance using medium grit, finish the process with fine grit sandpaper (1000 grit or higher). This final step is crucial for achieving a glass-like finish.

6. Clean Up After sanding, wash your print with soap and water to remove any residual dust. Allow it to dry completely before proceeding to any painting or additional finishing steps.

Final Thoughts

Sanding is an essential part of finishing resin 3D prints, allowing you to achieve a polished and professional look. By following the steps outlined in this guide, you'll be able to enhance your resin prints and prepare them for display or functional use. Remember to take your time, as rushing through the process can lead to unwanted scratches and uneven surfaces. Happy sanding!

Post time:Sep . 07, 2024 13:31

Next:Foundry Sand Services - Quality Sand Solutions for Metal Casting