Is Sand Casting Sustainable?

Sand casting, one of the oldest and most versatile metal forming techniques, has seen a resurgence in interest as industries strive for more sustainable practices. This traditional method involves creating a mold from sand to pour molten metal into, allowing for the production of complex shapes with relatively low costs and minimal waste. But in an era where sustainability is paramount, how does sand casting measure up?

Is Sand Casting Sustainable?

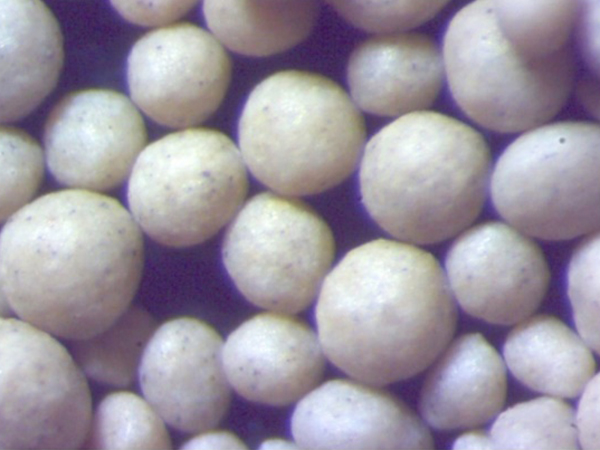

Another aspect to consider is the reusability of the materials used. Sand molds can often be reused multiple times before their quality diminishes. This reduces the need for new materials and can significantly minimize waste. In a circular economy context, upcycling used sand into other products or repurposing it for different industrial applications plays a vital role in promoting sustainability. Moreover, innovations like 3D printing of sand molds have emerged, allowing for more precise designs and further reducing material waste.

is sand casting sustainable

Furthermore, sand casting is relatively energy-efficient compared to other metalworking processes. The energy consumption associated with heating and melting metals can be optimized through better furnace technologies and practices. Many foundries are investing in renewable energy sources to power their operations, which further enhances the sustainability credentials of sand casting.

However, it’s essential to address the environmental impact of the chemicals often used in the process, such as binders for mold making. Many of these materials can be harmful to the environment, leading to air and soil pollution. Efforts are being made in the industry to find eco-friendly alternatives, which could substantially improve the overall footprint of sand casting.

In conclusion, while sand casting has sustainability challenges, there are numerous avenues for improvement. By focusing on responsible material sourcing, promoting reusability, leveraging energy-efficient practices, and transitioning to eco-friendly binders, the sand casting industry can move toward a more sustainable future. The traditional method is not yet fully sustainable, but with innovation and conscientious practices, it can evolve to meet modern environmental standards, thus paving the way for a greener manufacturing landscape.

Post time:okt . 07, 2024 23:39

Next:fine casting sand