Furthermore, environmental and regulatory considerations can affect overall cost. Facilities must comply with local environmental regulations that pertain to waste management and emissions, which can involve additional expenses for compliance, monitoring, and reporting. In some cases, foundries may need to invest in pollution control technology to meet stringent regulations, influencing the cost of operations. Despite these costs, sand casting offers several benefits that may warrant the investment. Its versatility is unmatched, as it can be used to cast almost any metal and create complex geometries. This flexibility makes it ideal for manufacturing a wide array of products from large machine components to intricate sculptures. Additionally, sand casting can accommodate a variety of sizes and weights, adding to its adaptability. When determining whether sand casting is an expensive option for a specific product, it's essential to conduct a thorough cost-benefit analysis. If a project demands high customization and adaptability without the need for high-volume production, the upfront costs may be justified. However, for long production runs, the cost per unit can become competitive with other casting methods. Considering expertise, experienced foundries often provide better value, as their proficiency can lead to optimized processes that save both time and resources. Companies with a track record of innovation and adherence to international standards instill confidence in the quality and reliability of the finished cast products. Therefore, collaborating with reputable service providers can ensure the most economical application of sand casting. In conclusion, the expense of sand casting cannot be viewed in isolation. While there are initial costs associated with materials, labor, and compliance, the process offers extensive benefits in terms of versatility and precision. Choosing sand casting should be informed by a project’s specific requirements, expected volume, and detail intricacies. For many applications, the investment is not only justified but advantageous when considering the technique’s immense capabilities and longstanding reliability. Post time:පෙබ. . 15, 2025 06:27

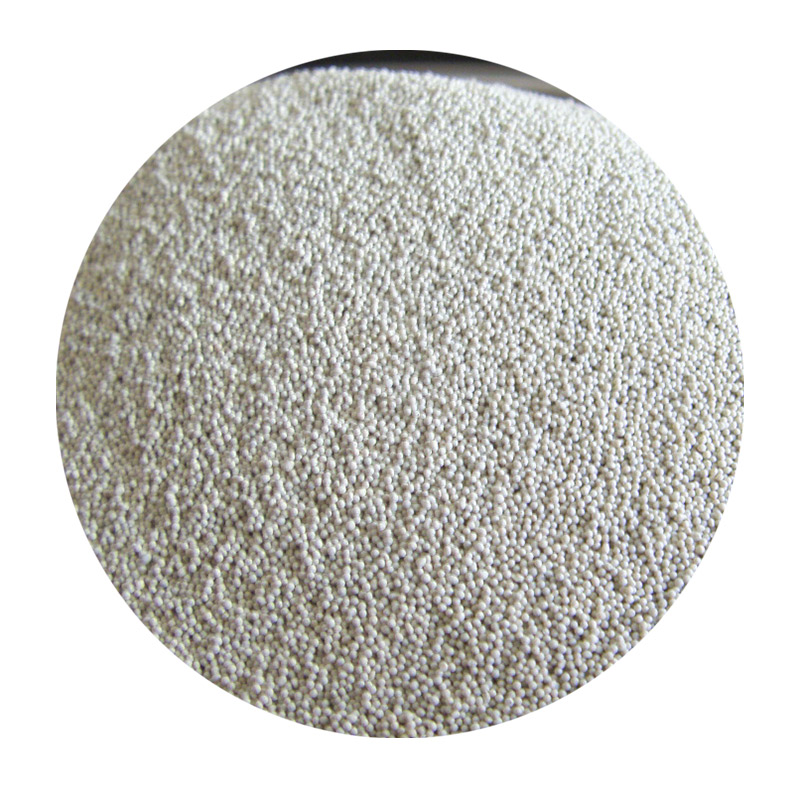

Next:Ceramic casting sand for sand 3d printing