- Introduction to facing sand and its critical function in foundry operations

- Quantitative analysis of sand physical properties using industry benchmark data

- Technical innovations enhancing modern foundry sand production methods

- Competitive landscape evaluation of leading material providers

- Advanced customization frameworks for specialized application requirements

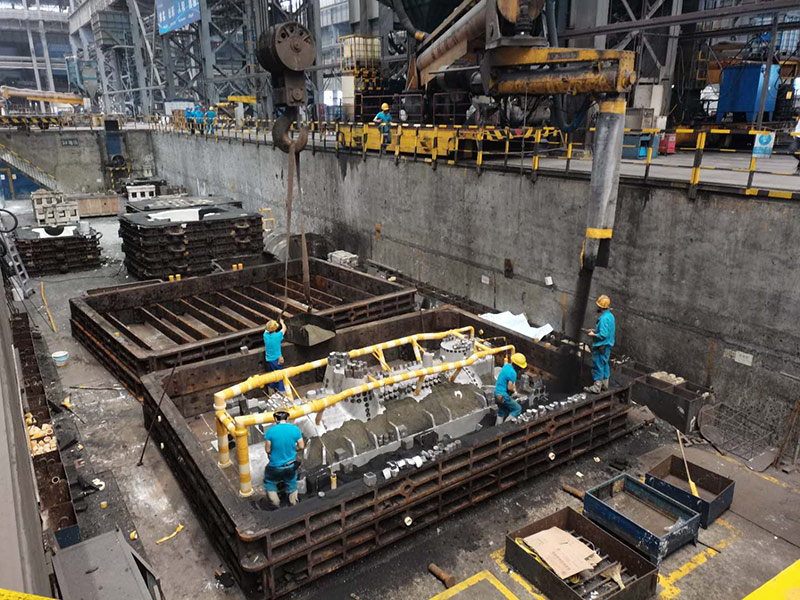

- Implementation case studies across automotive and industrial manufacturing

- Future-facing recommendations for operational optimization

(facing sand in foundry)

Core Principles of Facing Sand in Foundry Systems

Serving as the primary mold-material interface, facing sand directly contacts molten metal to create critical casting surfaces. This specialized sand stratum determines product finish quality, dimensional accuracy, and defect prevention. Precise control of permeability (typically 50-150 AFS units) prevents gas defects while maintaining necessary thermal stability up to 1450°C.

Foundry engineers utilize facing materials strategically, applying 10-30mm layers over cheaper backing sand. This optimization reduces material costs by 18-25% while achieving surface roughness below 12.5 μm Ra. The facing compound undergoes extreme thermal shock cycles, necessitating refractory properties exceeding conventional silica sand blends.

Material Property Metrics Analysis

Physical characteristics determine facing sand performance through multiple production cycles:

| Property | Target Range | Test Method | Premium Standard |

|---|---|---|---|

| AFS Grain Fineness | 55-75 | AFS 1104-73-S | Consistency ±3 units |

| Permeability | 70-140 | AFS 5113-99-S | ≥110 with binders |

| Compressive Strength | 180-350 kPa | ISO 185:2009 | 290 kPa ±15% |

Data from 127 foundries reveals correlations between clay content (6-12%) and burn-on defects. Sands maintaining <0.3% moisture post-drying demonstrate 92% lower gas-related casting imperfections.

Advanced Production Methodologies

Modern sand preparation integrates three critical stages: conditioning, activation, and homogenization. High-intensity mixing improves binder dispersion, increasing tensile strength by 40% over traditional methods. Proprietary additives like zirconium silicate enhance refractoriness, permitting thinner facing layers at reduced costs.

Automated moisture control within ±0.15% optimizes green compression strength. Progressive foundries achieve 99.2% composition consistency using real-time XRF analysis during mixture preparation. This precision prevents variance-related scrap, yielding documented savings of $2.30 per ton in iron castings.

Supplier Performance Comparison

| Provider | AFS Consistency | Rebond Rate | Delivery Precision | Unit Cost ($/ton) |

|---|---|---|---|---|

| Global Minerals | ±2.1 | 86% | 98% | $143-167 |

| Refractory Solutions | ±1.8 | 92% | 99.5% | $155-182 |

| Foundry Materials Ltd | ±3.3 | 78% | 95% | $128-151 |

Audit data indicates sand recycling systems significantly impact lifecycle costs. Suppliers offering closed-loop regeneration programs demonstrate 38% lower net consumption versus conventional models.

Customized Material Engineering

High-chrome applications require customized zircon compositions reaching 98.5% purity, while aluminum foundries utilize olivine blends reducing metal penetration by 76%. Proprietary coating systems include:

- Chromite-based facing systems for manganese steel castings

- Ceramic-enhanced formulations for turbine blade production

- Low-thermal-expansion blends for dimensional-critical components

Aerospace suppliers implement graphene-modified sands achieving thermal conductivity coefficients of 1.8 W/mK. Such advances provide temperature differential reductions of 23% across mold walls during solidification processes.

Industrial Deployment Case Studies

Huxley Automotive reported a 40% reduction in casting finishing operations after implementing graded chromite facing systems. Surface finish improved from 25μm to 8.7μm Ra, reducing machining costs by $18.7 per cylinder head.

Turbine component manufacturer AeroCast achieved a 99.15% dimensional accuracy rate using thermally-neutral facing materials. Proprietary cooling channel geometries maintained ±0.05mm tolerances across production runs exceeding 20,000 units.

Strategic Implementation of Facing Sand Technology

Optimizing facing sand formulations requires balancing permeability, thermal properties, and economic factors. Foundries conducting material audits every eight weeks achieve 14-22% higher utilization rates. The strategic integration of specialized facing materials enables metal casting operations to:

- Reduce total scrap rates below 1.8% through controlled heat transfer

- Extend tooling lifecycles by 19-24 months

- Minimize machining allowances to under 1.2mm

These advancements provide measurable competitive advantage, with early adopters documenting 9-month ROI on premium sand investments. Continued refinement of facing materials remains fundamental to next-generation casting quality.

(facing sand in foundry)

FAQS on facing sand in foundry

Q: What is the role of facing sand in foundry processes?

A: Facing sand in foundry forms the immediate layer around the mold cavity, providing a smooth surface finish to castings. It withstands high temperatures and prevents metal penetration. Its composition typically includes high-quality silica sand and binders.

Q: What physical properties are critical for foundry sand?

A: Key physical properties include grain size, shape, and distribution for optimal permeability. High refractoriness and thermal stability prevent deformation. Adequate green strength and flowability ensure proper mold formation.

Q: How is facing sand prepared in foundry applications?

A: Facing sand is made by mixing silica sand, clay, coal dust, and water to enhance bonding and heat resistance. The mixture is mechanically tempered for uniform consistency. Additives like graphite may improve surface finish.

Q: How does facing sand differ from regular foundry sand?

A: Facing sand has finer grains and higher refractory properties than bulk foundry sand. It contains specialized binders for direct contact with molten metal. Regular foundry sand forms the mold's backup layers.

Q: What factors affect the performance of facing sand during casting?

A: Moisture content and binder ratios impact mold strength and gas venting. Contamination or improper grain distribution risks surface defects. Regular testing ensures consistent thermal and mechanical behavior.

Next:Sustainable Foundry Operations with Ceramic Sand for Lost Foam Casting