Materials Used for Sand Casting

Sand casting is a widely utilized manufacturing process that involves pouring molten metal into a mold made from sand. This technique is well-regarded for its flexibility, cost-effectiveness, and ability to create complex shapes. The materials used in sand casting play a critical role in determining the quality of the final product. Here, we will explore the primary materials involved in this process.

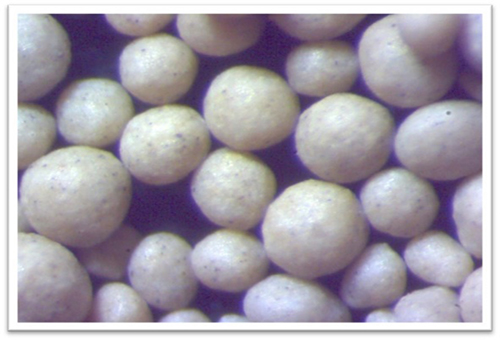

1. Sand The main material in sand casting is, of course, sand itself. The type of sand used is typically siliceous sand due to its high melting point and excellent thermal properties. The sand is mixed with a binder, usually clay, which helps to hold the sand grains together and maintain the shape of the mold. The quality of the sand is crucial; fine-grained sands provide a smoother surface finish, while coarser sands may result in a rougher texture.

2. Binders Binders are essential in sand casting to enhance the strength of the mold. Common binders include clay and synthetic resins. Clay, specifically bentonite clay, is the most traditional binder and is effective due to its adhesive properties when mixed with water. Synthetic resins, such as phenolic-urethanes, offer advantages like faster curing times and better mold strength, which can be especially important for complex or thin-walled castings.

what materials are used for sand casting

3. Metal Alloys The choice of metal alloy depends on the intended application and desired properties of the final product. Common metals used in sand casting include cast iron, aluminum, brass, and bronze. Cast iron is favored for its excellent fluidity, castability, and wear resistance. Aluminum alloys are lightweight and have good corrosion resistance, making them ideal for automotive and aerospace applications. Each metal alloy requires careful temperature control during the melting and pouring processes to prevent defects.

4. Coatings Mold coatings are often applied to the sand mold to improve surface finish and prevent the molten metal from sticking to the mold. Coatings can be made from various materials, including graphite and ceramic-based compounds. These coatings help reduce defects such as sticking and help provide a smoother final surface on the casting.

5. Additives To enhance certain characteristics of the sand mold and core, additives may be included. These can help with bonding properties, increase the mold’s permeability, or improve its heat resistance, leading to higher-quality castings.

In conclusion, the materials used in sand casting—sand, binders, metal alloys, coatings, and additives—play a critical role in determining the success and quality of the casting process. Understanding the nuances of these materials can significantly enhance the effectiveness of sand casting in various manufacturing applications.

Post time:Сен . 16, 2024 08:38

Next:steps in sand casting