Sanding 3D Prints A Comprehensive Guide to Perfecting Your Models

3D printing has revolutionized the design and manufacturing industry, allowing creators to bring their ideas to life with unprecedented ease and precision. However, despite the sophisticated nature of 3D printing technologies, printed models often require post-processing to achieve a professional finish. One crucial aspect of this post-processing is sanding, which can significantly enhance the aesthetic and tactile qualities of your 3D prints. This article will guide you through the processes, tips, and tools necessary for effectively sanding your 3D prints.

Understanding the Need for Sanding

When a model is printed, especially with common filaments like PLA, ABS, or PETG, it often has a rough surface due to layer lines, stringing, and other imperfections inherent in the additive manufacturing process. While these features are part of the charm of 3D printing, many users strive for a smoother, more refined look. Sanding helps to eliminate visible layer lines, create a better surface for painting, and improve the overall feel of the model.

Choosing the Right Tools

Before starting, it's essential to gather the appropriate tools for sanding your prints. Here are some items you will find beneficial

1. Sandpaper Various grit levels of sandpaper should be on hand. Start with lower grits (around 80-120) for significant smoothing and transition to higher grits (220-400 and above) for finer smoothing. Different materials may require different grit choices; for example, acrylic sandpaper may work better for certain plastics.

2. Sanding Sponges These are flexible and can conform to the contours of your model, making them especially useful for intricate designs.

3. Dremel Tool or Rotary Sander For those who prefer power tools, a rotary sander can speed up the process significantly. However, caution is needed to avoid overheating or melting the plastic.

The Sanding Process

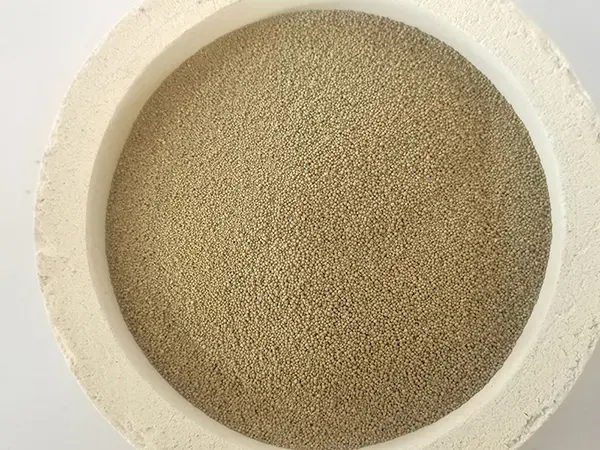

sanding 3d prints

1. Preparation Before sanding, ensure the print is cool and free from any loose debris or supports. Using a heat source like a heat gun can help in some cases to relax the plastic before sanding, but be careful not to deform your print.

2. Sanding Technique Start with the lower grit sandpaper and work in small circular motions or back-and-forth motions along the layer lines. Be cautious to avoid overly aggressive sanding that can damage the print. Focus on heavy areas of imperfection first, then gradually move to the finer grits, smoothing out the surface further.

3. Cleaning After sanding, use a brush or cloth to remove any dust particles. This step is crucial before applying any paint or finish.

4. Finishing Touches If you plan to paint the model, consider applying a primer after sanding to fill in any remaining imperfections. Once primed, you can paint your model as desired.

Common Mistakes to Avoid

- Rushing the Process Sanding takes patience. Rushing through can lead to uneven surfaces and more work in the long run.

- Using Too Coarse Grit Too Early Start with a medium grit before moving to coarse; too much aggressive sanding can gouge the print.

- Neglecting Safety Always wear a mask and goggles. Safety is paramount when working with any kind of particulate matter.

Conclusion

Sanding is an essential skill for anyone serious about achieving high-quality finishes on their 3D prints. By carefully preparing your tools, employing effective techniques, and practicing patience, you can transform a rough, printed object into a smooth, polished final product. With each print, you'll refine your skills and possibly even discover new methods specific to the materials you use. Embrace the sanding process, and watch your designs shine!

Post time:Дек . 23, 2024 00:04

Next:Пясок для інвестыцыйнага ліцця асаблівасці і перавагі выкарыстання