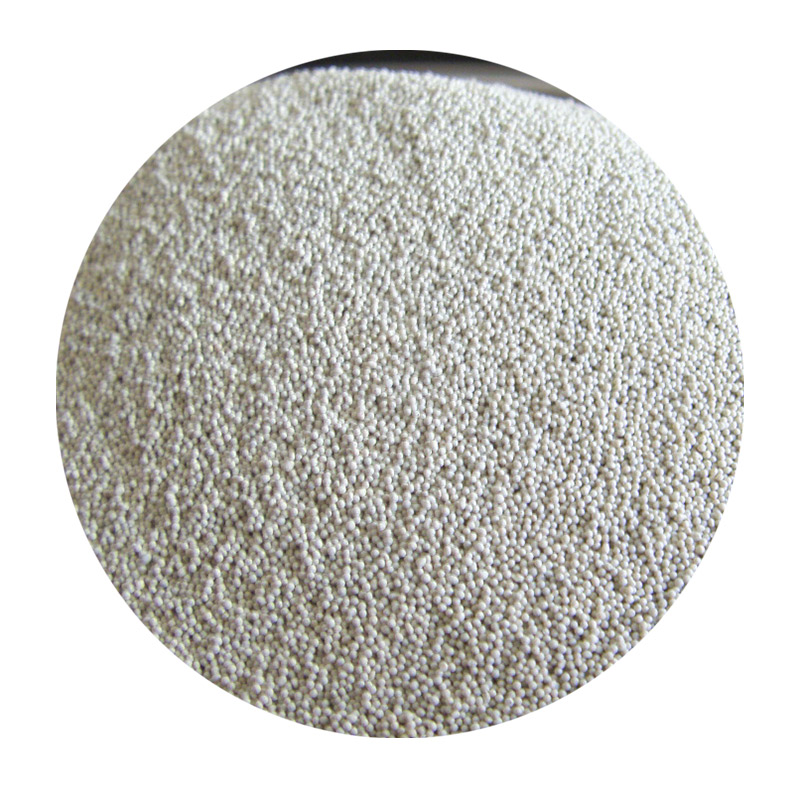

In heat-intensive industries, sand ceramic finds its niche for its superior thermal resistance. The material's ability to maintain integrity under high temperatures makes it ideal for use in kilns, furnaces, and even next-generation cookware. Industrial engineers appreciate its long-term cost benefits, citing its longevity and reduced need for frequent replacements. Authoritative voices in environmental engineering have endorsed sand ceramic as a leading solution in their quest for sustainable materials. Their studies underline its recyclability; post-use, sand ceramic can be broken down and reprocessed without significant degradation of its properties, vastly extending its lifecycle and utility. Trust in sand ceramic's potential is further cemented by rigorous testing and certification. Reputable laboratories have subjected this material to a gamut of tests, including stress analyses, weather exposure, and load-bearing assessments, all of which it has passed with commendable performance. This rigorous vetting process ensures that sand ceramic meets international standards for safety and efficacy, giving industry stakeholders confidence in its applicability. In conclusion, as industries and consumers become more conscientious about their ecological impact, the adoption of sand ceramic is expected to see substantial growth. Its blend of durability, sustainability, and versatility makes it a material of the future, ready to meet the demands of modern industries looking to innovate responsibly. Manufacturing leaders are poised to capitalize on sand ceramic's promise, driving the market forward while respecting the planet's finite resources. As the dialogue around sustainable materials intensifies, sand ceramic stands as a testament to human ingenuity and a beacon for sustainable transformation. Post time:feb. . 13, 2025 03:58

Next:Ceramic casting sand for sand 3d printing