3. Testing Perform a series of tests - Green Compression Strength Test Ensuring the sand can withstand pressure without deformation. - Permeability Testing Guarantees adequate gas escape during metal pouring, preventing blowholes. 4. Adjustment Based on the test results, adjust water content or modify clay percentage to enhance the mold characteristics. 5. Storage Post-mixing, store the foundry sand in a moisture-controlled environment to retain its properties until use. Practical Experience Insights Seasoned foundries understand that environmental conditions can significantly impact sand quality. Regular monitoring and slight adjustments are necessary to account for humidity and temperature variations. Additionally, recycling old sand while maintaining quality involves careful control of residual binder content. Expert Tips - Regular Maintenance Clean mixers and testing equipment after each batch to prevent contamination. - Detailed Record-Keeping Maintain accurate logs of material sources, batch compositions, and mold performance to trace any variances back to specific processes. Authority in Sand Selection Consult with casting experts or join foundry associations for up-to-date information on technological improvements and optimal material sourcing. Utilizing scholarly articles from established metallurgical research and adhering to industry standards—such as those from the American Foundry Society—can enhance authority. Building Trustworthiness Trust is built by demonstrating consistent outcomes in mold precision and durability. Provide transparency by sharing testing results and process alterations with stakeholders. Customer feedback should be actively sought to foster improvements. Developing a high-quality foundry sand requires a meticulous approach that integrates material science, precise engineering, and adaptive environmental management. By adhering to these best practices, foundry operators can produce sand that consistently meets the rigorous demands of modern metal casting industries. Post time:feb. . 07, 2025 02:49

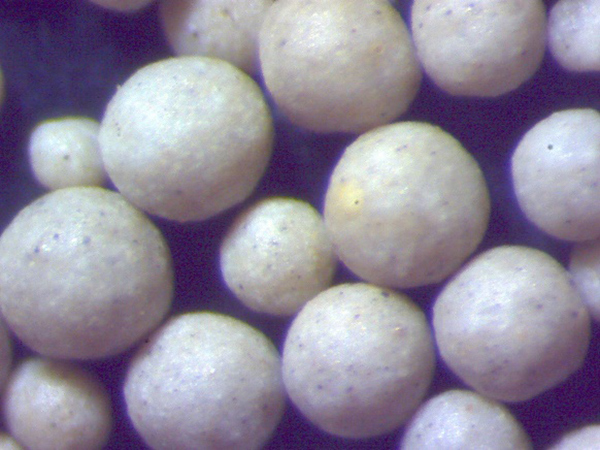

Next:ceramsite foundry sand